Manufacturing of stainless parts

Stainless steel machining has no secrets from us

Sabner – a trusted manufacturer of stainless steel parts

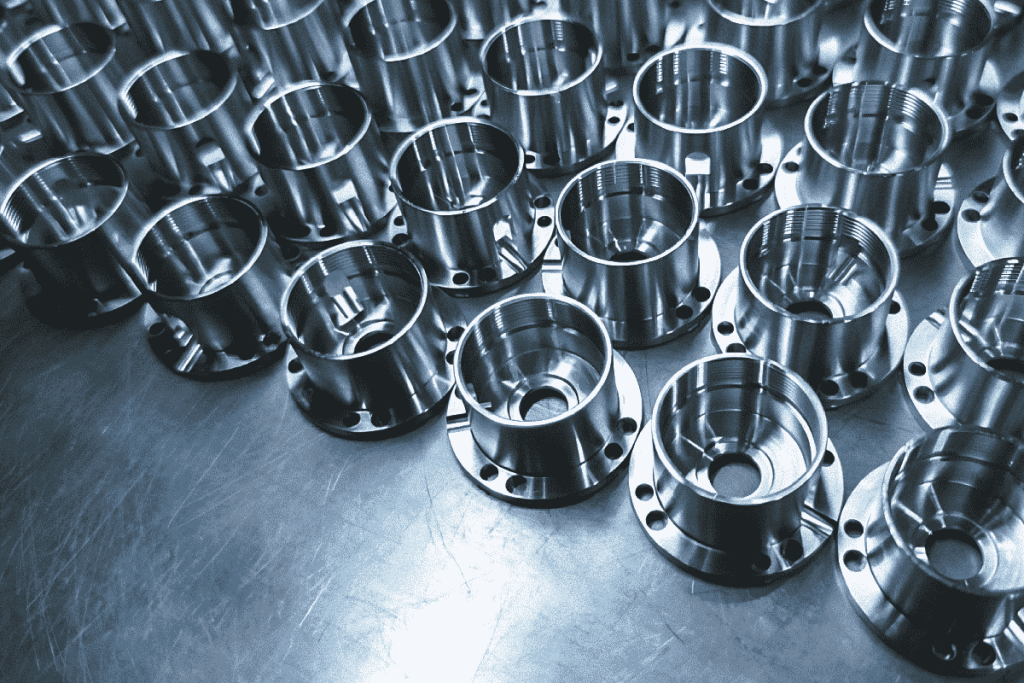

At Sabner, we have successfully created precision parts from stainless steel for the most demanding customers for years. We specialize in high-volume manufacturing on CNC automatic lathes of parts with a maximum diameter of 32 mm according to supplied specifications. We offer high precision of manufactured parts, short lead times, and transportation to the indicated location. We recommend that you take advantage of our services. If you need stainless steel parts, please contact our sales department. You will receive a quick and free quote for your project!

Why won’t it rust?

Shiny and durable – that’s how stainless steel can be described. Its attractive appearance and unique properties help create the most complex yet eye-catching structures. However, precision machining of stainless steel is very difficult, requiring extensive knowledge, experience, and the right choice of tools.

Stainless steel, also known as noble or INOX (from the French inoxydable – “non-oxidizing”), is a group of corrosion-resistant steel. Its unique physical and chemical properties allow it to effectively resist, for example, atmospheric agents (gaseous corrosion), dilute acids, or alkaline solutions (corrosion in liquids). According to the accepted standard, stainless steel is an alloy of iron, carbon (maximum 1.2%), and chromium (not less than 10.5%). The latter element is mainly responsible for its corrosion resistance since it forms a thin but durable protective layer when reacting with the oxygen and water contained in the air.

Child of the revolution

Stainless steel was discovered in France in the second half of the 19th century during the height of the Industrial Revolution. Metallurgists discovered through experimentation that the iron-chromium alloy had unique properties – it was resistant to rusting and acidic substances. Several decades later, independently, a new type of steel was patented in 1912 in Germany and 1913 in the United Kingdom of Great Britain. It was English engineer Harry Brearley who was the first to use the term “stainless” – ang. “rustless steel” (later, the name “stainless steel” was adopted in the English-speaking world).

Types of stainless steel

The multitude of combinations in forming iron alloys with various elements (it happens that manganese, silicon, nickel, and molybdenum are added to the alloy) means that today there are about 70 types of stainless steel. The proportions of the elements added affect the characteristics of the alloy created. Four main types of stainless steel have been distinguished based on composition, microstructure, and physical properties. At Sabner, we have mastered the technique of manufacturing parts from each of them:

Why stainless steel?

Corrosion resistance is not the only advantage of stainless steel. It has many other qualities, thanks to which parts manufactured from it are characterized by favorable parameters. The most important of these are:

Noble and demanding

Stainless steel can be daunting to machines. Due to its high strength, tendency to adhere, and low heat conductivity, cutting it on automatic lathes requires high competence. At Sabner, we have turning centers for the efficient machining of stainless steel. Proper training, knowledge, and experience allow us to effectively produce stainless steel parts in accordance with customer expectations.

Manufacturing of stainless parts at Sabner

At Sabner, we have been producing stainless steel parts on swiss type lathes for years. The high skills of our programmers and operators allow us to carry out even the most complex projects for many industries. So, if you’re looking for quality stainless steel parts and need a trusted manufacturer, please contact us!