Turned parts

We are a leader in precision turned parts manufacturing on automatic lathes.

What are turned parts?

Turned parts are machined parts formed by a manufacturing process called turning. The characteristic feature of these parts is their cylindrical shape resulting from the kinematics of the turning process, which involves cutting the rotating raw material to obtain the desired shape of the manufactured part.

Due to the great popularity of this manufacturing method, these parts are a very large group of components used in industry. These are all kinds of parts formed based on a rotating solid, such as shafts, bushings, rings, bolts, pins, and many others.

Turned parts manufacturing

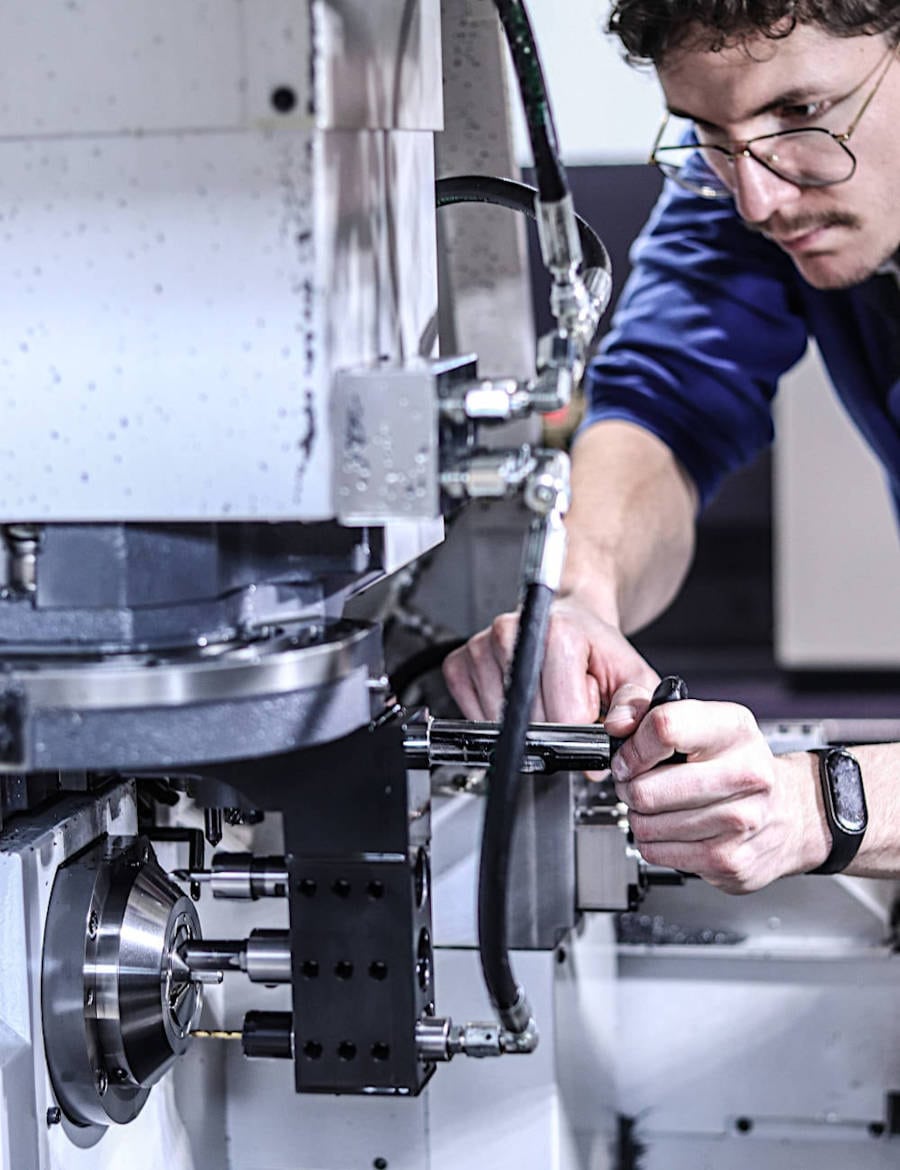

The widespread use of turned parts in almost all industries means that their manufacturing process must, above all, be very efficient. For this reason, modern computer-controlled machine tools adapted to the specifics of these components are used to produce parts.

For the production of large-turned parts, machine tools called CNC turning centers are used. These machines are very versatile, allowing the machining of parts with complex geometries. For components of smaller size, automatic lathes prove more useful, allowing efficient manufacturing of small parts in automatic mode.

When particularly tight dimensional tolerances are required of parts, standard manufacturing methods do not allow to achieve the desired accuracy while maintaining the dimensional repeatability of all parts in a production batch. In such cases, the following manufacturing methods are used:

Applications

Turned parts are used in many industries where the alignment accuracy, dimensional repeatability, and excellent strength characteristics are required. These parts can be produced efficiently, making them a popular choice for engineers designing modern mechanisms and equipment.

With the development of technology in the construction of modern machine tools and cutting tools, the technical possibilities that are available in the manufacturing process of these parts are expanding. This makes these parts present in almost every field, and the most popular examples are:

Materials

Due to the great flexibility of the CNC turning process, a very wide range of available materials can be used for turned parts manufacturing. Manufacturers of modern cutting tools continue to push the limits of the possibilities in this regard. Now, all kinds of metals and their alloys, plastics, and composite materials can be machined.

In industrial practice, however, most materials used for turned parts manufacturing are metals and their alloys. This is due to the good susceptibility of metals to shaping by machining. Due to their unique material properties, the most common in the industry are:

Supplier of turned parts

Sabner is a Polish company that manufactures precision turned parts for customers in various industries throughout Europe and abroad.

We specialize in precision turned parts manufacturing from various materials, including steel, stainless steel, brass, and titanium. Focusing on precision and efficiency, we use fully automated CNC machines to achieve unparalleled dimensional repeatability and productivity.

Our machinery is equipped with modern Swiss-type automatic lathes. This allows us to produce extremely precise parts, with tolerances measured in thousandths of a millimeter. All this is to provide comprehensive solutions and meet the high demands that precision turning of parts entails.

At Sabner, we are proud of our ability to offer customized solutions that meet the unique needs of each of our customers. Our group of experienced engineers closely cooperates with our clients to develop a deep and thorough comprehension of their specific requirements. In addition, we use the latest manufacturing technologies to ensure the highest quality of turned parts we produce.

Whether you need turned parts for aerospace, medical, automotive, or any other industry, Sabner has the expertise and resources to deliver the precision parts you need on time and budget.

Contact us today to learn more about our CNC turned parts manufacturing services and how we can help you achieve your production goals.