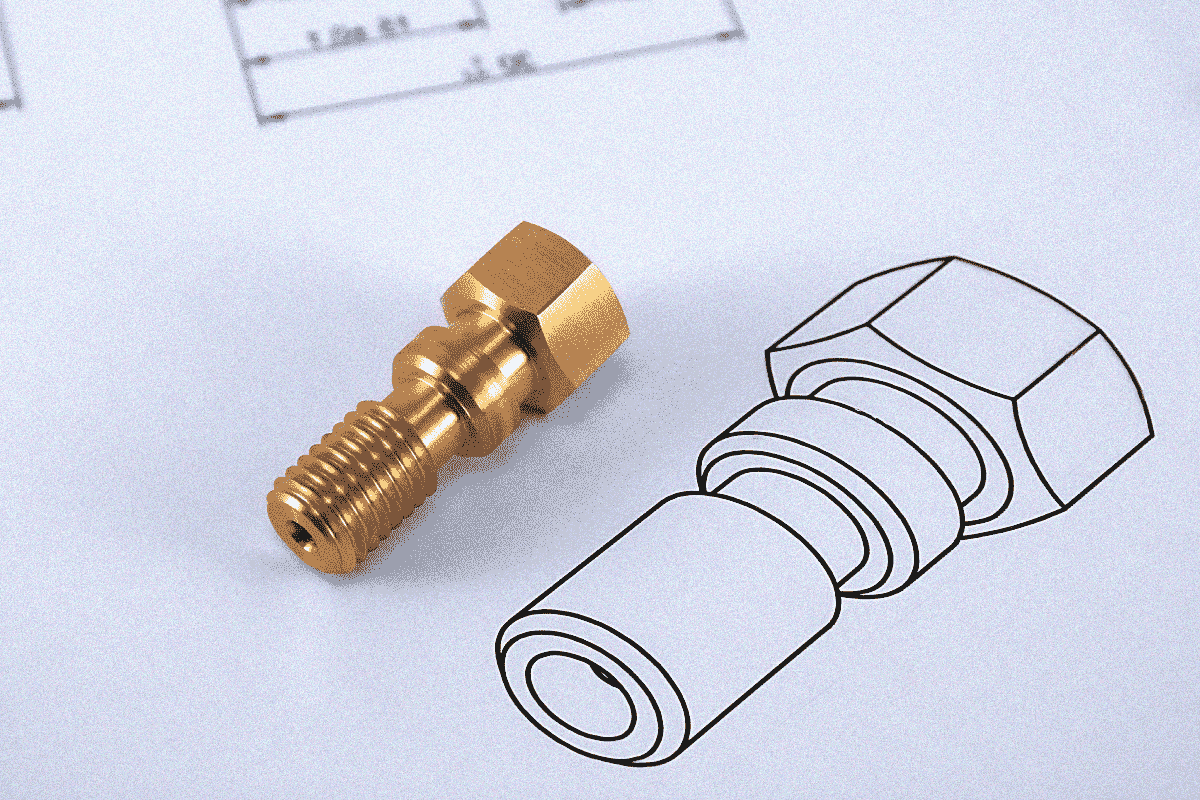

Brass parts manufacturing

Brass parts manufacturing is our specialty

Sabner – Brass parts manufacturing of the highest quality

Over the many years of Sabner’s metal machining business, we have developed an effective model of cooperation with customers. We specialize in high-volume manufacturing on swiss type automatic lathe machines of brass parts with a maximum diameter of fi 32. We manufacture parts according to the customer’s specifications and offer short lead times and transportation to any location. So contact us if you are looking for a trusted brass parts manufacturer. Our staff will take a look at your project and provide a free quote!

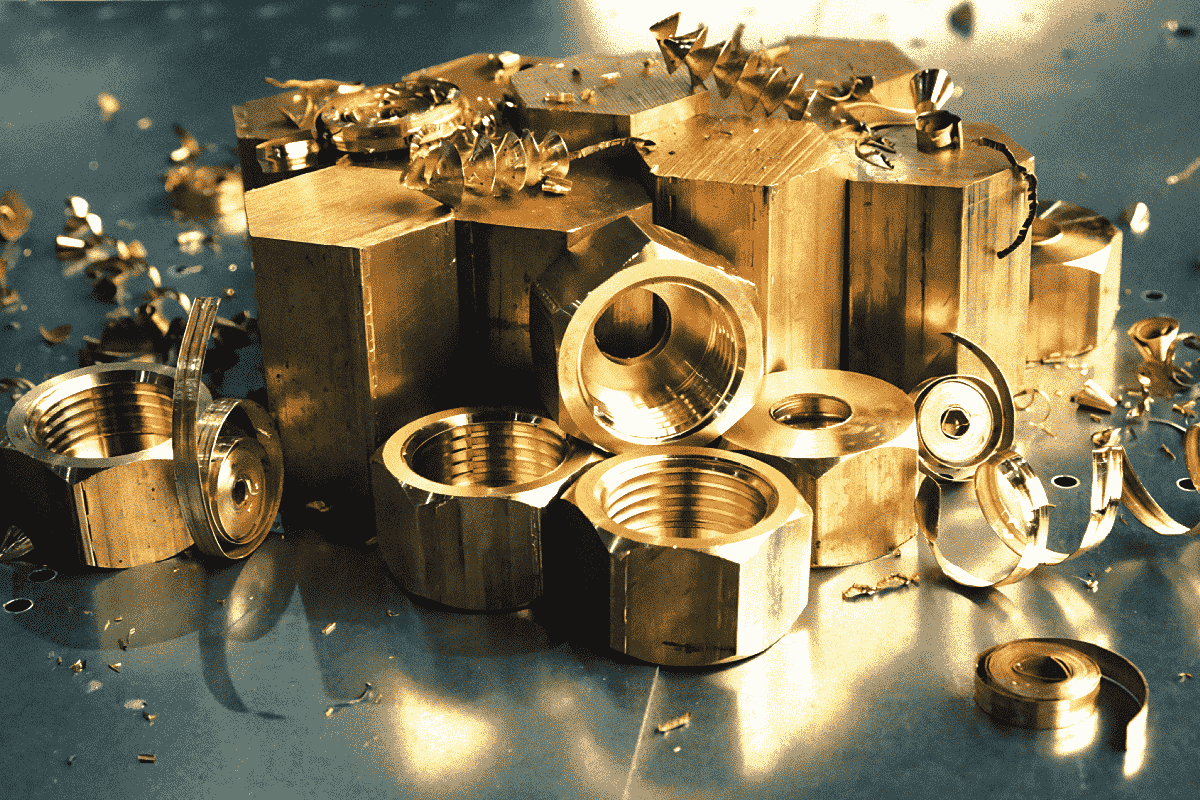

What is brass, and where does it come from?

Although it is centuries old, it still impresses with its form, and its unique character and excellent capabilities inspire appreciation. Brass, as it is referred to, is an alloy of copper and zinc, where the content of the second element does not exceed 45%. The remaining component is copper, and possibly small additions of other metals, such as aluminum, chromium, iron, tin, or manganese, are also possible.

The history of brass is long – it was used as early as ancient times, melting copper with zinc ores (smitsonite, hemimorphite), as evidenced by objects discovered during archaeological excavations. However, a milestone in brass manufacturing was mastering the zinc distillation process, which took place in Zawar (India) in the 9th century AD. From there, the technology came to Europe, albeit many centuries later, as late as the first half of the 18th century. Since then, the possibilities offered by producing parts from an alloy of copper and zinc have been used more and more boldly.

Appearance and advantages of brass

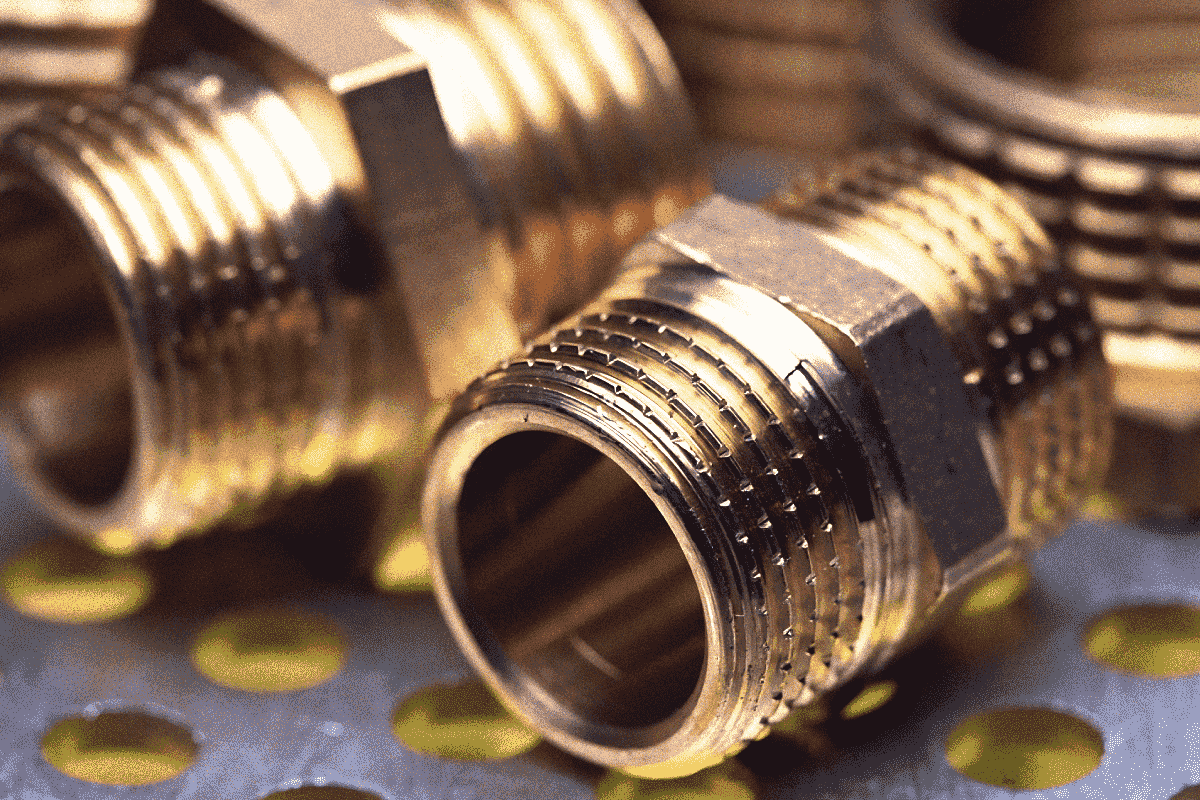

The first thing that strikes the eye is the orange-yellow or golden-yellow color of brass (the color depends on the zinc content – the more, the more orange). Moreover, as with other copper alloys, its surface is covered with a bluish-green patina due to oxidation, protecting it from external agents and corrosion.

Brass is more durable than other alloys, especially various steel grades. It is also characterized by excellent thermal conductivity and electrical conductivity, ranging from 23-44% of the conductivity of pure copper. In addition, it is favorably distinguished by its high flexibility and elasticity and relatively high density (8.44 to 8.75 g/cm3), which translates into its weight. These characteristics make it well suited for machining, so at Sabner, precision manufacturing of brass parts is a crucial part of the business. We use several types of brass for manufacturing:

Application of brass

At Sabner, we have experience in manufacturing brass parts for various industries. Below are some of them:

Best quality, short deadlines

You have come to the right place if your company needs precision brass parts. We offer high-quality manufacturing, short lead times, and the ability to ship to your desired location. At Sabner, we manufacture top-quality brass parts for every industry, from the hydraulic industry to the automotive industry. We use the highest standards, which allow us to create brass parts up to fi 32 in diameter. Send us your project, and we will prepare a free quote for you!