Machining

What is machining with CNC machining machines?

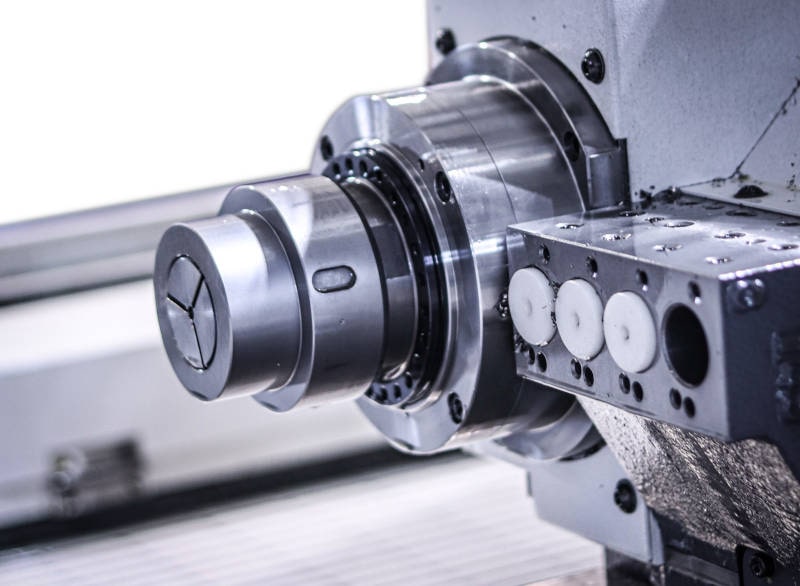

It is a manufacturing technology of various parts by removing excess material from an initial block called a blank or workpiece. This process takes place on machine tools, which allow the controlled removal of successive layers of material using special cutting tools.

It is a process that requires both high-level specialists in technology and CNC machine tool programming. Modern machine tools allow very efficient manufacturing of metal parts, but it is necessary to program them properly.

In addition to qualified specialists, precision machining also requires modern cutting tools. At Sabner, we realize the importance of their proper selection, so we perform our services using equipment from reputable suppliers such as Sandvik, Kennametal, and Mitsubishi Materials.

What does CNC mean?

A popular acronym often used in the manufacturing industry, it comes from the words Computer Numerical Control. It means that the computer is responsible for controlling the machine’s movements. This method is a more modern version of the conventional machining widespread in the last century when an operator was responsible for controlling the machine. He used a series of levers, knobs, and buttons to direct the machine’s movements personally.

What are the basic methods of machining?

It is one of the methods of producing metal parts using appropriate machine tools and cutting tools. Due to the specifics of the process, there are two basic methods of machining: CNC milling and CNC turning. Each of them has its characteristics and is suitable for the manufacturing of a specific type of parts.

What is the step-by-step machining process?

The basics of this process include the following steps:

What type of documentation is appropriate?

In industrial practice, we have to deal with many types of production documentation, from working on a physical model of an object through classic drawing documentation to advanced spatial models. The most important thing is to provide the contractor with an unambiguous definition of the geometric features of the object. The most common formats of technical documentation in our industry are:

Remember that the more detailed the documentation, the more efficient and faster the manufacturing process.

What materials can be machined?

The range of materials suitable for machining is very wide. The most common materials used in the industry are:

Each group has its unique properties desired by designers of modern objects. So, machining engineers constantly overcome new limitations to expand the range of its possibilities to include more materials.

How long does it take to machine a part?

In this process, production preparation time and the time it takes to make a single part should be treated separately. Due to the enormity of the factors affecting the size of these times, it is impossible to determine them unequivocally. However, in some simplification, the production preparation time is much longer than the time of parts manufacturing itself. Process preparation times are in the order of a few hours or days. CNC machining times for parts usually range from a few seconds to tens of minutes.

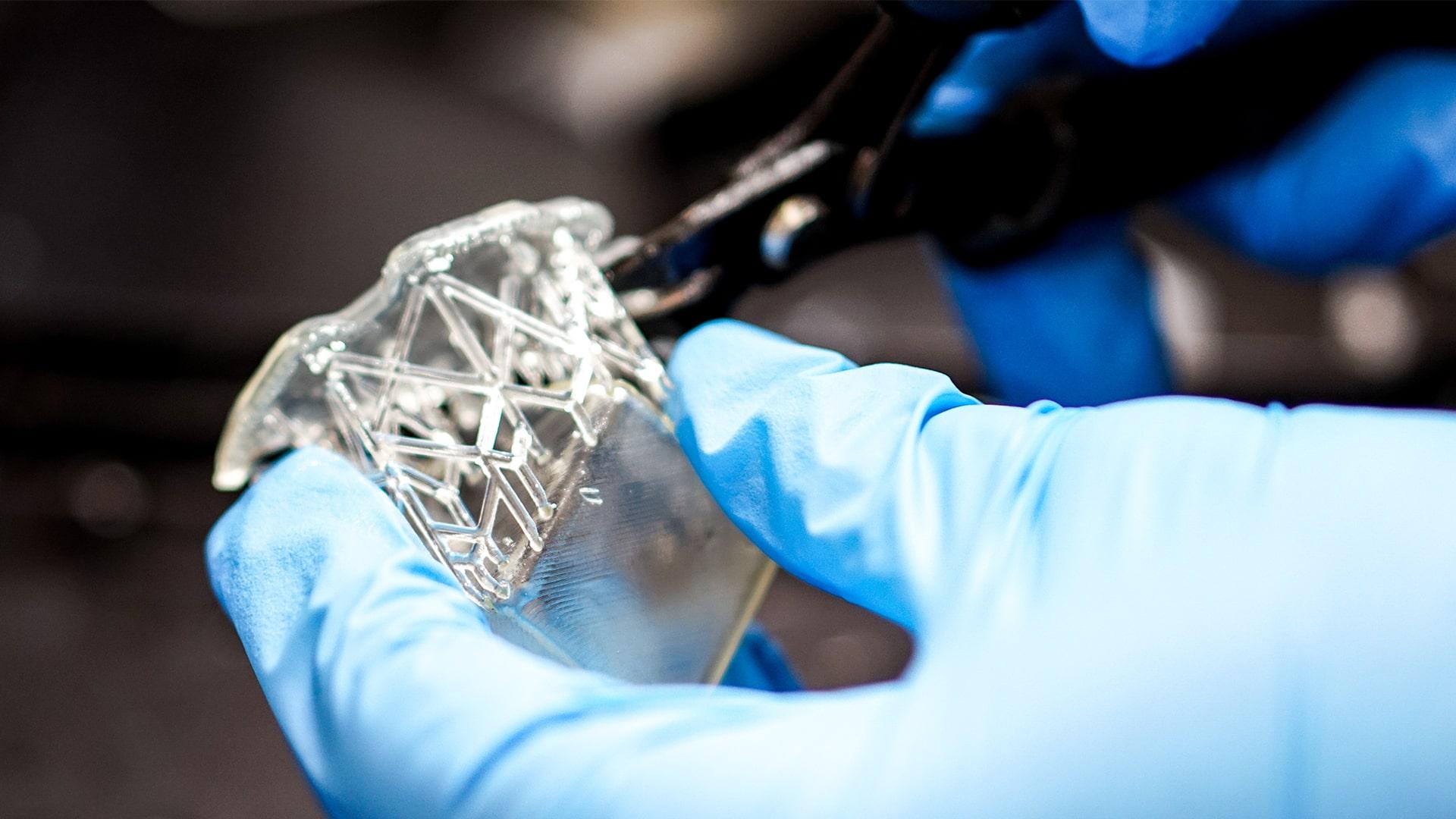

What products can be made by machining?

Despite the rapid development of alternative manufacturing technologies such as 3D printing, machined parts are virtually all around us. From automotive parts to household appliance components to jet or space rocket components. Factors behind the popularity of this method include:

What other information is important?

When sending your request for a quotation to a contractor, it is worth providing as many details as possible that define a specific project. Depending on what is already on the attached documentation, it is necessary to specify several key factors that affect the correct choice of process and lead time:

Machining at Sabner

It has been a core of the business at Sabner since its founding. Over decades of operation in the demanding CNC machining market, we have accumulated the necessary experience and expertise in efficient metal machining. This has allowed us to gain the trust of a wide range of companies looking for a proven and reliable partner in the metal parts manufacturing industry.

Possessing a versatile and modern machine park consisting of one hundred percent numerically controlled machine tools means that machining most of the materials available on the market is not the slightest problem for us. Due to market demand, the basis of our current offer is metal machining. Among the materials we process most often are steel, including stainless steel and brass.