CNC Turning general knowledge

CNC Turning general knowledge

Turning is the oldest machining method known to humankind. The first signs of lathes use date back to ancient Egypt, where tools were used to work on a rotating object. This took place around the 13th century BC.

It was only in the Industrial Revolution in the 18th century that the advancement of turning technology started to pick up pace. Lathes began to become larger, more complex, and more powerful. The use of steam and hydropower allowed for more advanced designs. Similarly, introducing electric motors marked another stage in the technical development of these machines.

The last milestone in the development of turning machines came after the end of World War II when numerical control systems were developed. Of course, the initial solutions had little in common with modern CNC controls. However, it completely changed the way we think about operating machines. Since then, there has been a constant refinement of the capabilities and autonomy of machining processes.

CNC turning – what is it?

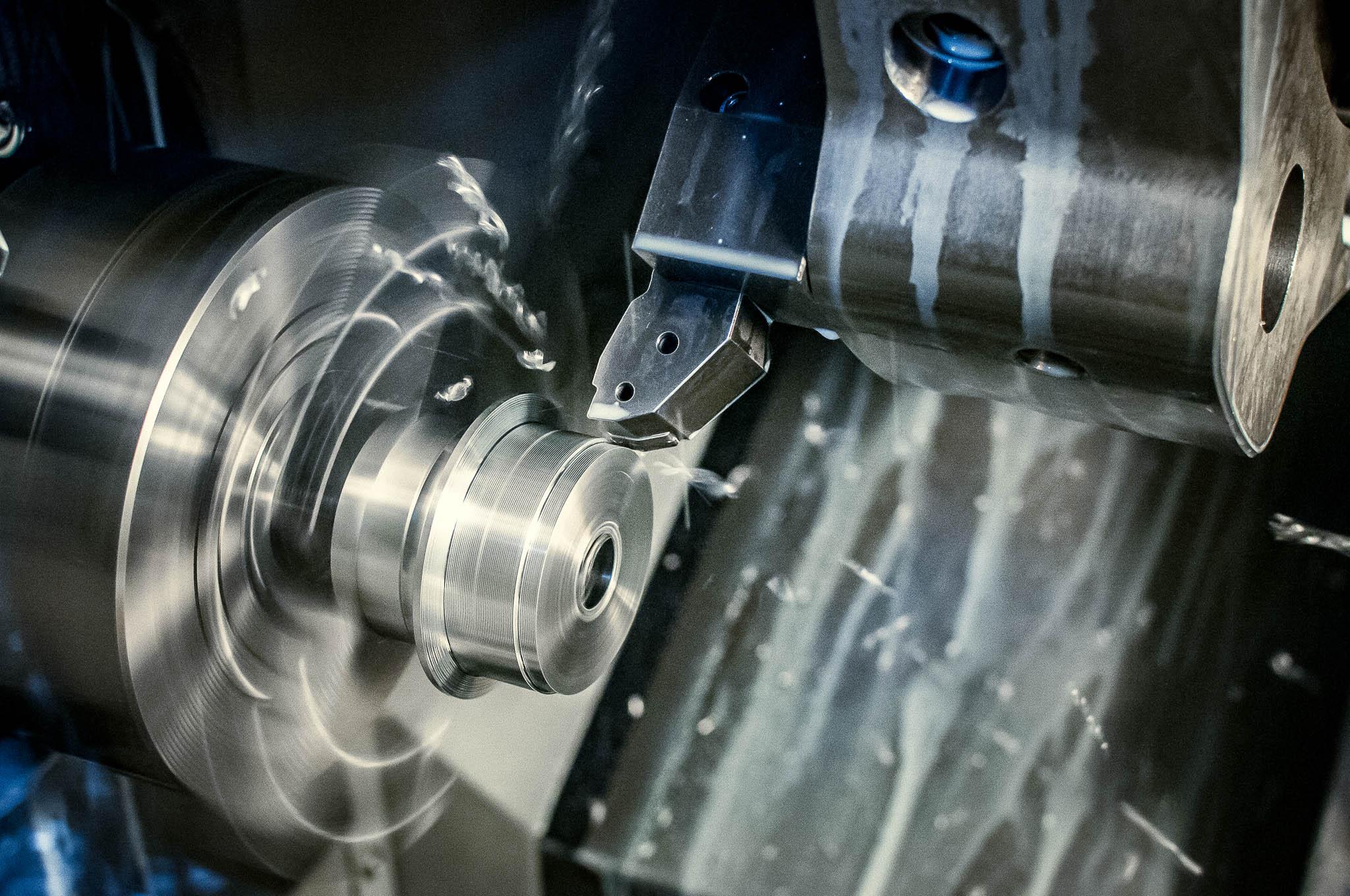

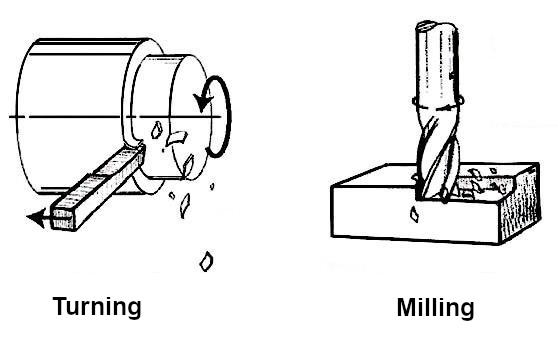

To understand CNC turning, one must first understand the nature of the turning process itself. Turning is a method of manufacturing parts that involves cutting material from a piece of material rotating around its axis. The material is often in the form of a bar and clamped in the lathe chuck. The cutting is done with special tools that can separate a piece of material in a well-defined way to leave what we designed as our part.

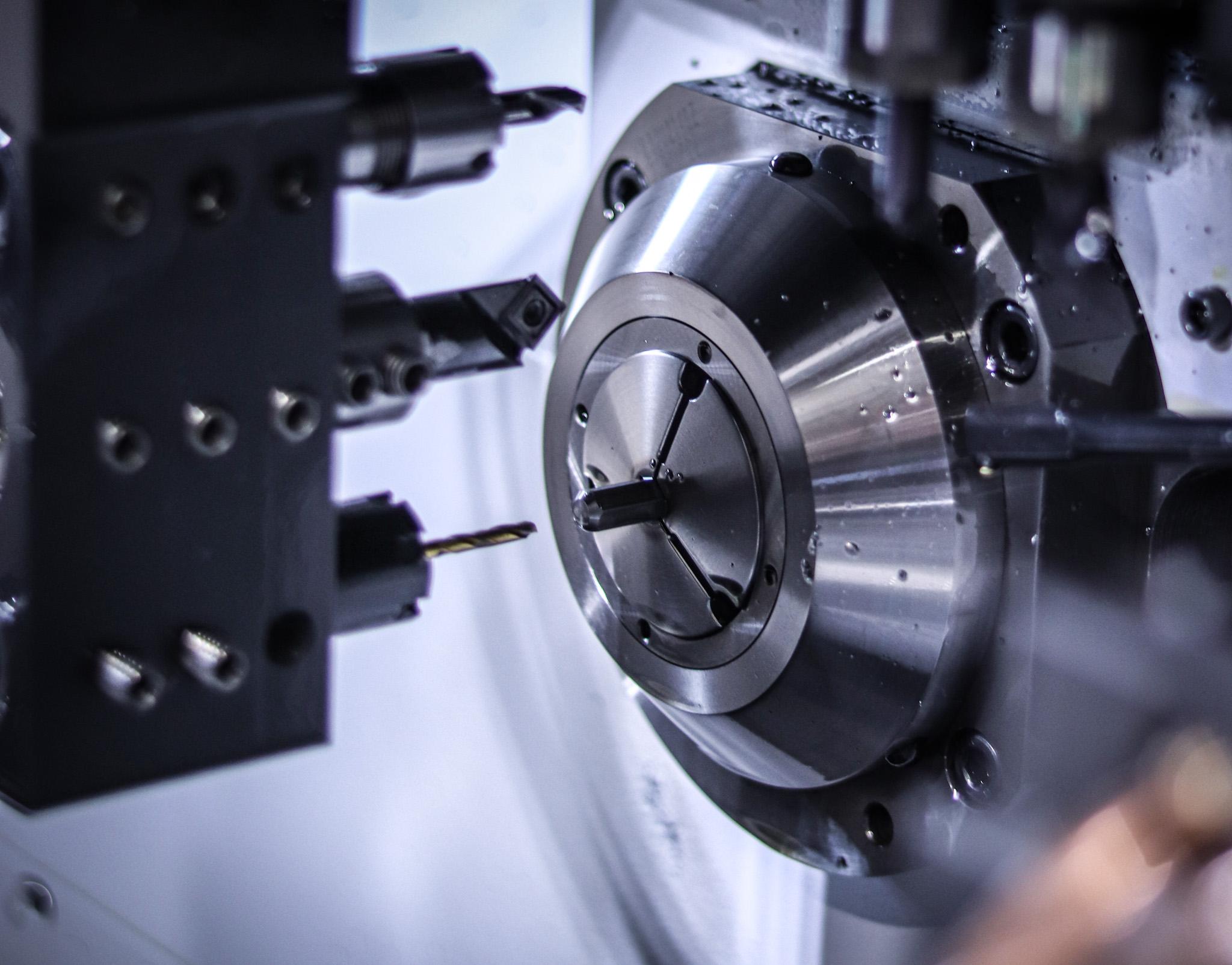

CNC turning differs from the turning described above in that it is done on computer-controlled machines. The principle of the process is identical. However, the CNC control gives much more scope for shaping parts. This is due to the fact that a computer is responsible for the movements of the machines. Thus, inaccuracies and mistakes are eliminated.

What are the differences between CNC turning and CNC milling?

Although both methods belong to machining technology and therefore involve creating parts by removing material, there are a few key differences between the two methods:

What materials can be machined by CNC turning?

CNC turning is a very flexible process when it comes to machining a variety of materials. The development of modern cutting tools is constantly expanding the range of available materials suitable for processing with CNC turning centers. However, below is a short list of those most common and typical for this type of machining:

What parts can be produced on CNC lathes?

Due to its attributes, the CNC turning process enables the manufacturing of a diverse array of components. The development of modern machines somewhat blurs the distinction between lathes and milling machines due to the construction of multi-task machining centers. However, considering the typical lathe process is dedicated to producing components in the form of rotary solids. Therefore, all kinds of bars, axles, bushings, cylinders, rings, wheels, cones, washers, bolts, and many more are made on lathes.