Threaded bushings

We manufacture threaded bushings for all industrial applications.

Sabner – manufacturer of threaded bushings

Sabner is a leading manufacturer of a wide range of threaded bushings made to customer specifications, strictly according to the specifications received. Manufacturing is carried out at our modern plant in Poland on precision CNC automatic lathes. With years of experience in precision manufacturing, we can offer our customers fast lead times and competitive prices. Entrust your project to the experts and send us your request to manufacture bushings.

What is a threaded bushing?

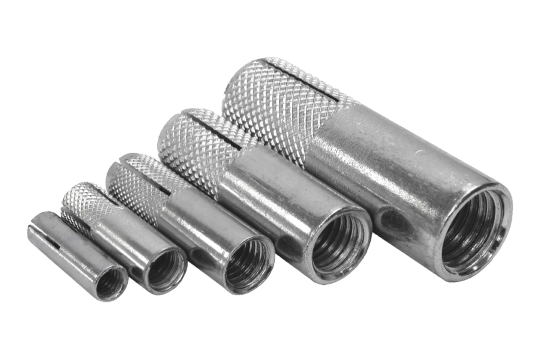

A threaded bushing is a fastener assembled to add a hole to make a solid and durable bolted connection. Often, steel is used for these parts, including stainless steel and metal alloys, such as brass. In the case of bushings made of steel, it is practiced to protect them additionally with galvanizing.

This helps strengthen the corrosion resistance of the components, which increases the durability and safety of the connections created with them. The standard designation of threaded bushings is as follows: M5 x 0.8, where “M” indicates the type of thread (here: metric), “5” – is the nominal diameter, and 0.8 – is the pitch of the thread.

What are threaded bushings used for?

Threaded bushings often create new, powerful connections in wood, plastics, or metals like steel and brass. In addition, these bushings can be used to repair damaged threads (self-tapping sleeves manufactured at Sabner are excellent for this) and to change threads from inch to metric and vice versa.

However, making an effective threaded connection in some materials is possible only. This may be due to the material’s properties – brittleness or too much softness, but also the shape of the material. For example, creating a practical and durable threaded connection in very thin sheet metal is very difficult.

Types of threaded sleeves

At Sabner, we manufacture threaded bushings of various types. They are widely used in leading industries because they meet the highest technical and quality requirements. Below are our most important products of this type:

Manufacturing of the highest quality

At Sabner, we manufacture threaded bushings from high-grade steel or brass per customer requirements. We can manufacture and deliver threaded bushings with diameters up to phi 32 to the designated location according to the specifications provided by our customers.