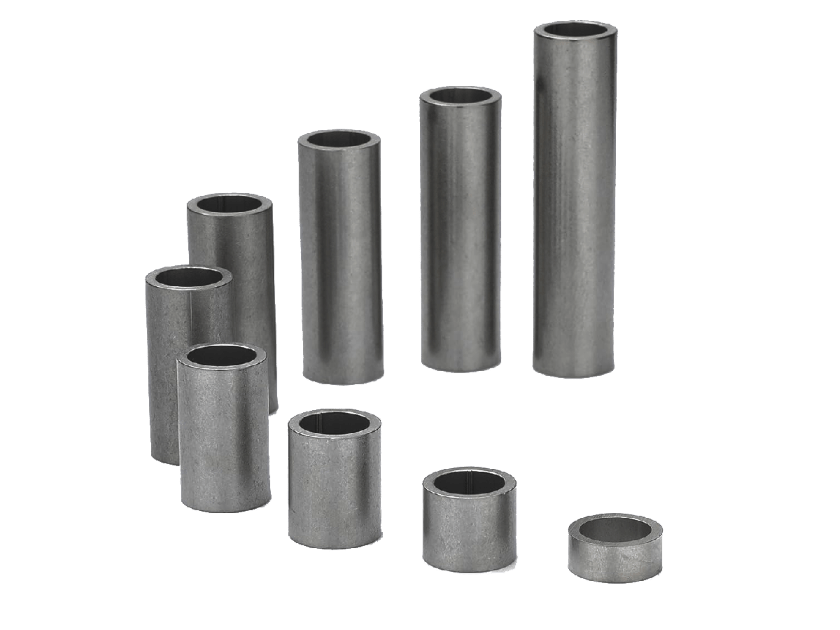

Spacer sleeves

We are a leading manufacturer of spacer sleeves

Manufacturing spacer sleeves at Sabner

Spacer sleeves manufactured at Sabner are used in almost every industry. Many years of experience in machining on Swiss type automatic lathes help us create parts of the highest quality and precision. In turn, cooperation with customers from various industries allows us to adapt to market requirements quickly. As a result, we can offer short lead times and competitive prices. If you need spacer sleeves for your business, ask for a free quote.

Spacer sleeves – how do they work?

These sleeves, also known as through sleeves, are not impressive in size, but it is difficult to imagine any smoothly running machine without them. These parts have a body with a circular or hexagonal (hexagonal) cross-section and mounting elements on one or both sides: internal threads, external threads, snaps, or combinations thereof.

The task of spacer sleeves, as the name implies, is to provide a constant distance between components to ensure the proper functioning of entire systems. The length of the bushing body defines the distance between components of the structure. In addition, spacer sleeves are also used to reduce friction, control movement, or provide adequate insulation. They are installed in small everyday devices, as well as in vehicles and even advanced production lines.

Types of spacer sleeves

Since spacer sleeves are used in various mechanisms, they must have the right parameters regarding shape and size. When choosing the right one, other equally important factors should be considered, such as strength, corrosion resistance, electrical insulation, weight, operating temperature, or vibration and noise absorption. Hence, the material used to make through-hole sleeves is extremely important. Typically, stainless steel, aluminum, and brass are used for their manufacturing. Nevertheless, they can also be made of plastic and even rubber.

Application of spacer sleeves

Spacer sleeves are an integral part of modern technology. Thanks to these inconspicuous parts, it is possible to use functional devices with which it is easier to imagine daily life. Spacer sleeves prove that seemingly complex structures consist of many simple solutions. Where can they be found, and what functions do they perform?

Challenges of the highest quality

Sabner specializes in high-volume manufacturing of spacer bushings according to customer-supplied specifications. We offer transportation of our products to the specified location. Years of experience in machining steel, stainless steel, aluminum, and brass enable us to manufacture the highest quality bushings with diameters up to phi 32. Sabner’s long presence in the metal machining market helps meet the most demanding orders. See for yourself and ask for a free quote for your project. Send us your project!