Tool steels and alloys

Table of contents

Tool steels are materials specially adapted for the production of tools used in machining, plastic working, and measurement. Their task is to meet specific and often very demanding working conditions, which can vary significantly depending on the application. Unlike structural steels, for which there are precise indicators that characterize their properties, the evaluation of tool steels is primarily based on the analysis of their chemical composition and a set of mechanical and physical requirements.

In Polish standards, tool steel has been classified into four main groups: carbon tool steel, alloy steel for cold working, alloy steel for hot working, and high-speed steel. Regardless of this classification, there are also specialized tool materials such as cast alloys and sintered carbides, which perform well in extreme conditions.

Characteristics of tool steels

Tool steels are a specialized group of materials designed for the manufacture of tools that operate under high mechanical and thermal loads. Their uniqueness lies in the fact that they must combine high hardness, abrasion resistance, strength, and dimensional stability, even under extreme operating conditions. It is these properties that determine their suitability for the production of knives, drills, dies, injection molds, and measuring tools.

One of the most important requirements for these steels is their ability to maintain high hardness after hardening, which often exceeds 60 HRC. Such high hardness allows other materials to be machined without the risk of excessive blade wear or loss of tool geometry. However, resistance to brittle fracture and the ability to absorb the energy of dynamic loads are equally important, ensuring the durability and reliability of the tool when working in variable conditions.

Another key aspect is hardenability, i.e., the ability of the material to achieve a uniform structure with high hardness throughout the entire cross-section. In the case of large tools, this is a decisive factor in their effectiveness, as non-uniform hardening would weaken the structure. Equally important is resistance to tempering, which allows the tool to operate at elevated temperatures without losing its mechanical properties, especially in tools designed for hot work.

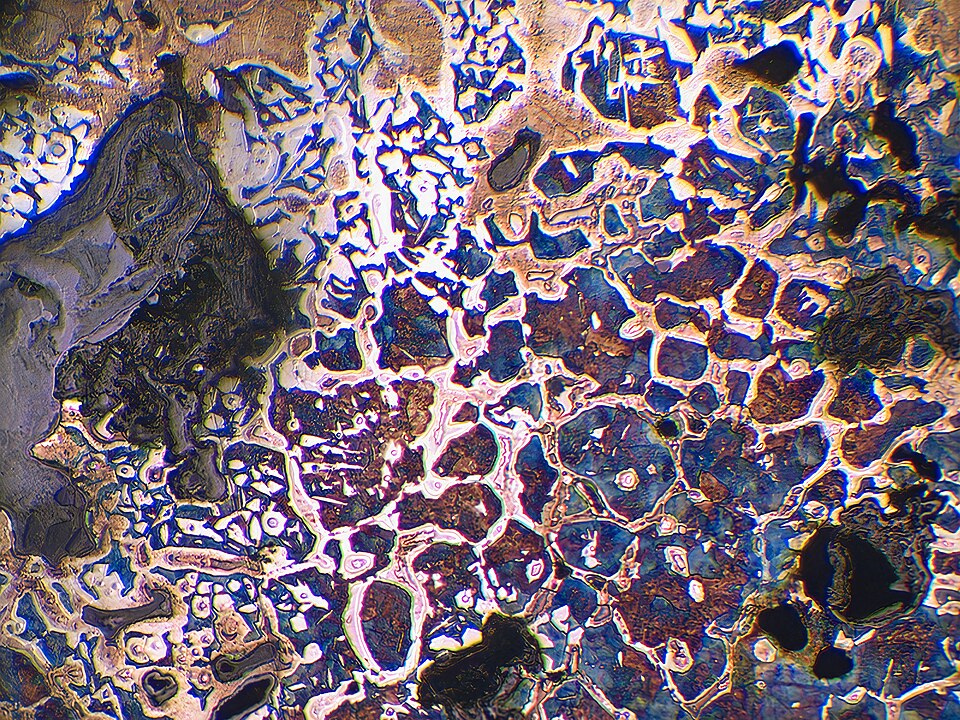

A significant factor influencing the properties of tool steel is its chemical composition, which typically includes substantial amounts of carbon and alloying elements such as chromium, tungsten, vanadium, molybdenum, and cobalt. In addition to strengthening the structure by forming hard carbides, these elements also provide the effect of so-called secondary hardness – i.e., the ability of the material to regain high hardness after heat treatments such as tempering. All these features make tool steel one of the most advanced engineering materials, whose properties must be precisely tailored to a specific application.

Carbon tool steel

Carbon steels occupy a special place among tool steels, as they are the simplest and historically the oldest group of materials used for tool production. Their basic feature is a high carbon content, typically ranging from 0.5% to 1.3%, which enables them to achieve the hardness necessary for tool work. Despite the lack of alloying additives, carbon steel can achieve excellent performance properties, provided that it is adequately heat-treated.

The high carbon content enables this steel to achieve considerable hardness after hardening, making it suitable for use at room temperature, particularly in tools designed for manual processing, such as files, knives, chisels, and saws. The key limitation of these steels is their low resistance to elevated temperatures – already at around 200°C, there is a noticeable decrease in hardness, which excludes their use in tools for hot work or at high machining speeds.

Carbon tool steel also exhibits moderate wear resistance – although sufficient for low-intensity applications, it does not match alloy steels in this respect, especially those containing carbides. Its advantages, however, remain its ease of heat treatment and low price, which means that it is still widely used in general-purpose tools and single-unit production.

It is worth noting that the performance properties of these steels are highly dependent on the quality of the raw material and the precision of the hardening process. Even slight deviations in the austenitizing temperature or tempering time can result in significant changes to the microstructure and, consequently, the material’s behavior during operation. For this reason, carbon tool steel requires a carefully selected heat treatment technology, adapted to the type and shape of the tool.

Despite certain limitations, carbon tool steel remains important. In many cases, it remains the optimal choice from an economic and functional standpoint, especially where working conditions are not extreme and precision is of key importance.

Alloy tool steel for cold working

Alloy tool steels for cold working are a crucial group of materials used in tools subjected to high mechanical loads but operating at low temperatures, typically not exceeding 200°C. It is thanks to these characteristics that they can be successfully used in cutting, stamping, forming, and cold punching processes, where maintaining blade durability and wear resistance is crucial without risking thermal weakening of the structure.

A distinguishing feature of these steels is their rich chemical composition, which, in addition to carbon, includes alloying additives such as chromium, tungsten, vanadium, and molybdenum. These elements not only increase hardenability, enabling high hardness to be achieved in large tool cross-sections, but also form very hard and stable carbides. This provides the steel with excellent abrasion resistance, which is particularly important in applications where the tool comes into contact with hard materials or must maintain precise cutting edges for an extended period.

One of the most important properties of this group of steels is also dimensional stability during heat treatment, which is particularly important in the production of dies, punches, molds, and measuring tools. Precision components made of cold-work alloy steel can be hardened without risk of deformation, resulting in a long service life and reliability in operation.

It is also worth noting that this steel is characterized by good resistance to cracking, resulting from a carefully selected microstructure and the presence of elements stabilizing the crystal lattice. Its ability to absorb impact energy and maintain ductility even at high hardness levels makes it indispensable in many tools used in variable stress conditions.

Alloy steels for cold working are, therefore, an advanced material whose properties can be precisely adjusted through the appropriate selection of composition and controlled heat treatment. Their versatility makes them one of the most commonly used materials in tool production, where wear resistance, precision, and durability are absolute priorities.

Alloy tool steel for hot working

In applications where tools must operate under conditions of significantly elevated temperatures, often exceeding even 600°C, it is necessary to use special alloy tool steels adapted to such extreme conditions. Hot work steels are designed to maintain high hardness, wear resistance, and structural and dimensional stability despite intense heating and cyclic temperature changes.

The key factor determining their suitability is their ability to maintain their mechanical properties under high-temperature conditions. Unlike carbon steels, which lose a significant part of their hardness at 200°C, hot-work steels must retain their rigidity and resistance to deformation even in much more demanding thermal environments. As a result, they are used, among other things, in the production of dies for forgings, molds for metal die casting, punches, and heat treatment tools.

These properties can be achieved by using appropriately selected alloying additives, such as chromium, molybdenum, tungsten, and vanadium. Their presence not only improves hardenability and creates stable carbides, but also prevents the material from softening during prolonged exposure to high temperatures. This effect is called secondary hardness and is particularly desirable in this group of steels.

No less important is resistance to thermal fatigue, i.e., the ability of the material to withstand cyclic thermal stresses resulting from heating and cooling. Hot-work steels must counteract the formation of thermal microcracks, which could lead to rapid tool degradation. That is why so much importance is attached to their structure and a precisely controlled heat treatment process, which ensures a uniform and stable microstructure throughout the entire cross-section of the tool.

Thanks to these properties, hot work tool steels are irreplaceable in applications where traditional materials fail. Their use directly translates to the durability, reliability, and safety of industrial processes, where tools operate under extreme thermal and mechanical loads.

High-speed steels

High-speed steels occupy a unique position among tool steels, as they are materials specifically designed for use in highly demanding metal cutting conditions – both at high speeds and under intense heat. Their unique combination of properties makes them widely used in the production of cutting tools, including drills, milling cutters, taps, and turning tools.

These steels are distinguished primarily by their ability to maintain high hardness even at temperatures of 500–600°C, making them ideal for high-speed machining. This feature, known as red-hot hardness, enables a significant increase in cutting process efficiency without compromising the tool’s cutting edge. Importantly, even under such extreme working conditions, high-speed steels retain their mechanical properties and exhibit excellent resistance to abrasion and plastic deformation.

The high efficiency of these materials is due to their rich chemical composition, in which, apart from carbon, large amounts of tungsten, molybdenum, vanadium, chromium, and sometimes cobalt dominate. The presence of these elements enables the creation of extremely hard carbides and complex phase structures, which are responsible for exceptional wear resistance and hardness retention at elevated temperatures. The result of this composition is also high hardenability and structural stability, even in large tool cross-sections.

The properties of high-speed steels can be further modified through precise heat treatment processes, including multi-stage hardening and tempering, which allow for optimal stress distribution and microstructure stabilization. As a result, tools made from these steels are not only highly durable but also highly reliable in demanding production conditions.

High-speed steels remain irreplaceable in many industries, particularly where the performance, precision, and durability of tools directly impact the quality and efficiency of the entire manufacturing process.

Other tool materials

Although tool steels form the basis of most tools, there are also other groups of materials that, due to their specific properties, play a key role in the most demanding technological applications. Among them, sintered carbides, tool ceramics, and super-hard materials such as boron nitride and synthetic diamond occupy a special place.

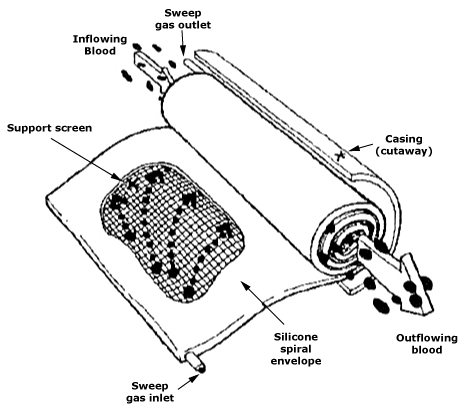

Sintered carbides, also known as cemented carbides, are materials formed by combining tough particles, most often tungsten carbide, with a metallic binding phase, most often cobalt. This combination results in a material with exceptional hardness, abrasion resistance, and the ability to operate at extreme temperatures that no steel could withstand. Sintered carbides are commonly used in cutting tools, especially where it is necessary to maintain a sharp cutting edge at high speeds for extended periods.

Another group is tool ceramics – materials based on oxides, nitrides, or non-metallic carbides. Although they are more brittle than steels and carbides, their extremely high hardness and resistance to high temperatures make them ideal for precision machining of hard materials, especially in the automotive and aerospace industries.

The most advanced industrial applications also use super-hard materials such as cubic boron nitride (CBN) and polycrystalline diamond (PCD). CBN is ideal for machining hardened steels, offering unparalleled wear resistance and thermal stability. In contrast, diamond, although limited to non-ferrous materials, offers the highest hardness known in engineering. Tools made of these materials are used in applications where the requirements for durability, accuracy, and performance are incredibly high.

However, the use of such specialized materials requires not only advanced production technology but also appropriate working conditions, including precise geometry, control of cutting parameters, and stable clamping systems. Their implementation results in higher costs, but at the same time, it brings significant benefits in the form of shorter production times, improved quality, and extended tool life.

In this way, modern tool technology extends beyond the traditional realm of steel, entering the realm of advanced engineering materials whose properties are precisely tailored to specific technological challenges.

Tool steels and alloys – summary

The selection of the right tool material is not just a technical issue – it is a strategic decision that affects the efficiency, quality, durability, and economy of the production process, whether it is a simple cutting operation, advanced plastic working, or precision measurements.

This choice requires in-depth knowledge of the physical, mechanical, and thermal properties of individual steels and other tool materials. Carbon steels, although economical, are not suitable for applications where the tool is exposed to intense heating. Alloy steels, on the other hand, enable the design of durable, resistant tools that operate in demanding conditions, whether for cold or hot work. High-speed steels, with their exceptional hardness at high temperatures, have revolutionized machine cutting, and materials such as sintered carbides and CBN have opened the door to unparalleled durability and precision in the most demanding industrial applications.

In modern materials engineering, optimization is what counts. The tool material must be selected not only for its strength but also for its dimensional stability, ease of machining, wear resistance, cost, and suitability for the operating conditions. In this context, knowledge of material properties is not an add-on; it is a fundamental tool for the engineer.