What is stainless steel?

Table of contents

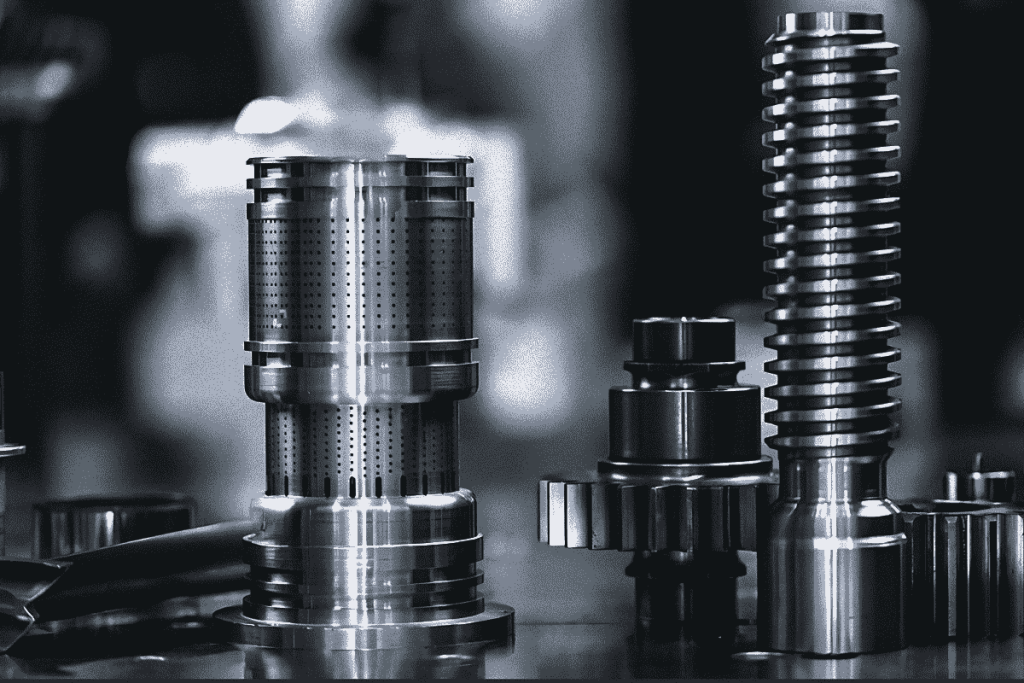

Stainless steel is one of the most important developments in metallurgy of the 20th century. Since its invention, it has become a key material in many industries, from construction and mechanical engineering to medicine and gastronomy. Its unique properties distinguish it from traditional iron alloys, notably its corrosion resistance, strength, and elegant, shiny appearance.

Its history dates back to the late 19th century when experiments with alloying additives revealed that introducing chromium into steel significantly enhanced its rust resistance. The breakthrough occurred in 1913 when English metallurgist Harry Brearley unveiled the first stainless steel, which gained recognition for its anti-corrosion properties.

Properties of stainless steel

Stainless steel, also known as INOX (from the French inoxydable, meaning “non-oxidizing itself”), is a group of steel alloys characterized by enhanced corrosion resistance. The key element that gives it this property is chromium, the minimum content of which is 11% according to the American AISI standard. When it comes into contact with oxygen, it forms a thin layer of chromium oxide on the surface of the steel, called the passive layer. This is a self-repairing layer – even after scratching or damage in the presence of oxygen, it rebuilds itself, preventing further material degradation. Among the basic properties of stainless steel are:

- Corrosion resistance – due to its chromium content, stainless steel is resistant to weathering, acids, alkalis, and chemical solutions. Sometimes, nickel, molybdenum, or nitrogen are added to increase resistance to aggressive environments.

- Mechanical strength – stainless steel is a material with high hardness and resistance to dynamic loads and abrasion. Its mechanical properties vary according to its microcrystalline structure, which allows it to be widely used in industry.

- High-temperature resistance – some grades of stainless steel can operate at extreme temperatures, making it ideal for the aerospace, energy, and automotive industries. This resistance is mainly due to alloying elements such as chromium, nickel, and molybdenum, which stabilize the material’s structure and prevent it from degrading at high temperatures. In addition, ferritic steels and some martensitic steels show increased resistance to oxidation and thermal deformation.

- Shiny mirror and aesthetics – stainless steel’s distinctive surface makes it a popular choice in architecture and design. It can be polished, brushed, or matte, depending on your needs.

- Hygienic and easy to clean – stainless steel does not absorb contaminants due to its structure. It is easy to maintain and is used in the food, pharmaceutical, and medical industries. In addition, studies show that stainless steel is more resistant to microbial growth than aluminum or copper.

Types of stainless steel

Stainless steel is not a homogeneous group of materials; several main types depend on its chemical composition and microcrystalline structure. This division makes it possible to tailor the properties of steel to specific industrial, structural, and everyday applications. The basic types of stainless steel are:

|

Name |

Main components |

Features |

Typical species |

Application |

|---|---|---|---|---|

|

Austenitic steel |

Chromium (16-25%), nickel (6-22%), sometimes molybdenum and nitrogen |

|

|

Cutlery, pots, chemical tanks, installations in the food and pharmaceutical industries |

|

Ferritic steel |

Chromium (10.5-30%), minimal or no nickel |

|

1.4016 (AISI 430) – commonly used in household appliances |

Household appliances, automotive, exhaust systems, decorative facades |

|

Martensitic steel |

Chromium (10.5-18%), carbon (0.1-1.2%) |

|

1.4021 (AISI 420 – used for knives and surgical instruments) |

Knives, surgical instruments, shafts, springs, turbines |

|

Ferritic-austenitic steel (duplex) |

Chromium (19-32%), nickel (3-10%), molybdenum (up to 5%) |

|

1.4462 (AISI 2205 – used in chemically aggressive environments) |

Chemical industry, petrochemical industry, offshore construction, drilling platforms |

|

Precipitation hardening (PH) stainless steel |

Chromium (15-17%), nickel (3-5%), alloying additives (copper, aluminum, titanium) |

|

17-4 PH (AISI 630 – used in the aerospace industry) |

Aerospace, defense, turbine industry |

Each type of stainless steel has unique properties that make it ideal for specific applications. Austenitic stainless steel dominates everyday use, while ferritic and martensitic steels are used in motorization and tooling. Duplex and PH steels are used in the most demanding environments, such as the marine industry and aviation. Thanks to this diversity, stainless steel remains one of the most important materials in the modern world.

Stainless steel production process

The production of stainless steel is a complex process that requires precise control of the chemical composition and appropriate processing. Each step, from the selection of raw materials to melting and forming to final processing, affects the final properties of the material.

The first step is the selection of raw materials and batch preparation. The basic stainless steel component is iron (Fe), to which the appropriate alloying elements are added. The key element is chromium (Cr), which forms a protective layer on the surface of the steel to protect it from corrosion. Other important additives include nickel (Ni), which increases ductility and resistance to high temperatures; molybdenum (Mo), which improves resistance to acids and salts as well as carbon (C), which affects hardness; and nitrogen (N), which increases mechanical strength.

Raw materials are then remelted in smelting furnaces. The electric arc furnace (EAF) is primarily used for this purpose, allowing the use of scrap steel and, thus, the recycling of the material. An alternative is a converter furnace, which is used mainly in steel mills. In this furnace, oxygen blown into the molten metal removes unwanted admixtures. This process allows the correct chemical composition of the steel to be obtained.

Once the steel has been smelted, it is necessary to further purify it and reduce its carbon content. For this purpose, the AOD (Argon Oxygen Decarburization) process is used, which involves blowing argon and oxygen into the liquid metal to remove excess carbon without losing valuable elements such as chromium or nickel. Alternatively, the VOD (Vacuum Oxygen Decarburization) process is used, which takes place under vacuum conditions and produces steel of even higher purity. Thanks to these methods, stainless steel is characterized by high uniformity and corrosion resistance.

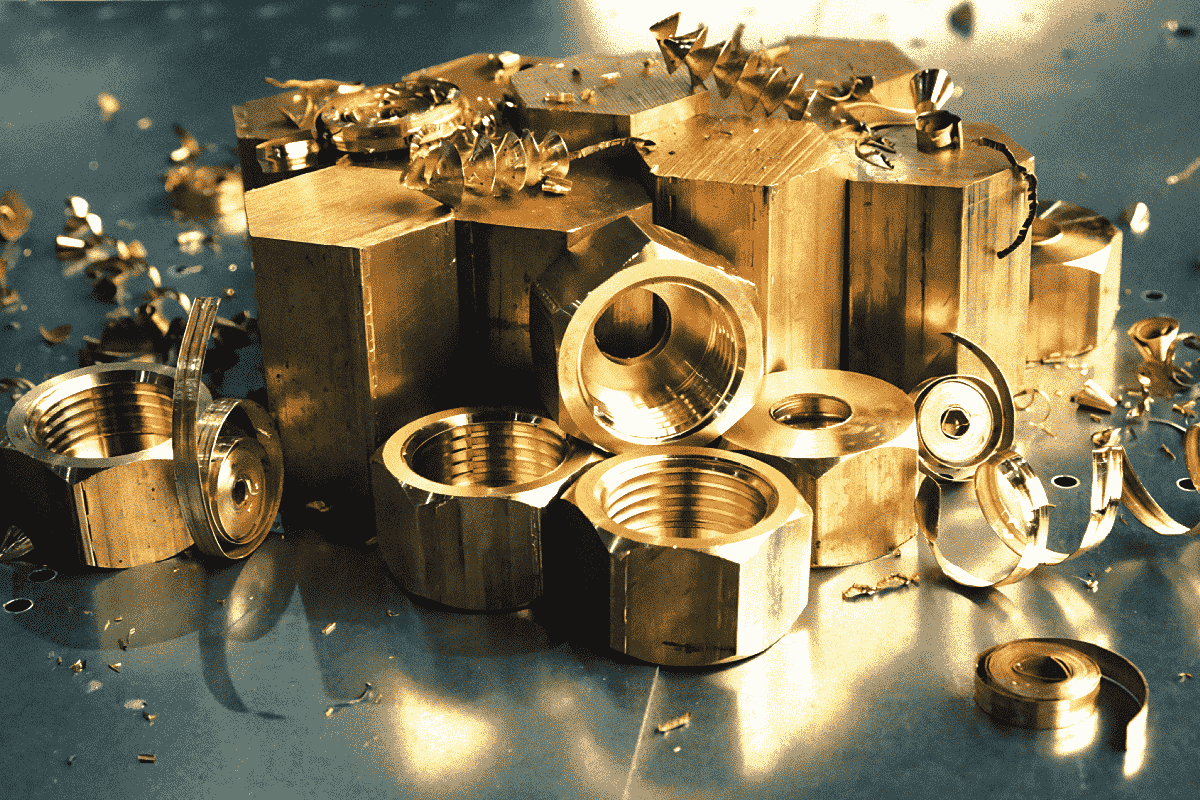

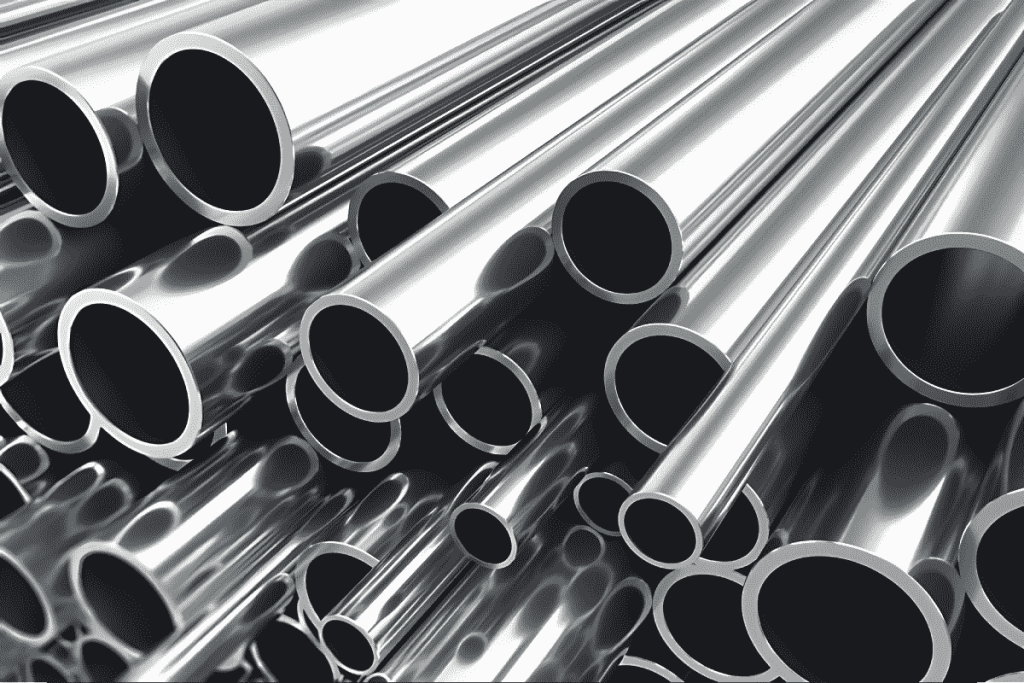

The next step is forming and casting the steel. Continuous casting (CC) is used to produce semi-finished products such as steel sheets, bars, pipes, or strips. Traditional mold casting is used for more complex shapes, allowing the production of finished parts with precise dimensions. At this stage, the steel can be hot-rolled, which improves its mechanical properties and eliminates internal stresses.

Casting is followed by thermal and mechanical treatment to further improve the material’s structure. Hot rolling reduces the thickness of steel sheets, while cold rolling further increases their strength. Depending on the type of steel, hardening and tempering, which improve the material’s hardness, or annealing, which reduces stresses and improves corrosion resistance, are also used.

The final stage is post-treatment and surface finishing. Depending on its intended use, stainless steel can be polished to achieve a glossy finish or brushed to give it a matte appearance. Passivation, which is the chemical strengthening of the protective chromium oxide layer, is used to increase corrosion resistance. Finally, the steel is cut and formed according to the customer’s requirements – this can be traditional mechanical cutting or modern laser techniques that ensure high precision.

The production process of stainless steel involves many complex steps crucial to its final properties. Thanks to modern processing methods, steel is widely used in industry, construction, and everyday life, remaining one of the most important engineering materials of the 21st century.

Applications of stainless steel

Stainless steel is one of the most commonly used materials in industry and daily life. Its unique properties, such as corrosion resistance, mechanical strength, aesthetic appearance, and ease of maintenance, make it useful in many industries. Thanks to the different varieties of stainless steel, its properties can be adapted to specific conditions of use.

One key application area for stainless steel is the food industry. Steel is used to manufacture tanks, pipes, and fittings for food and beverage processing. Its resistance to corrosion and ease of cleaning make it meet the stringent hygiene standards required for contact with food products. Stainless steel is also used to manufacture cutlery, pots, pans, and cookware.

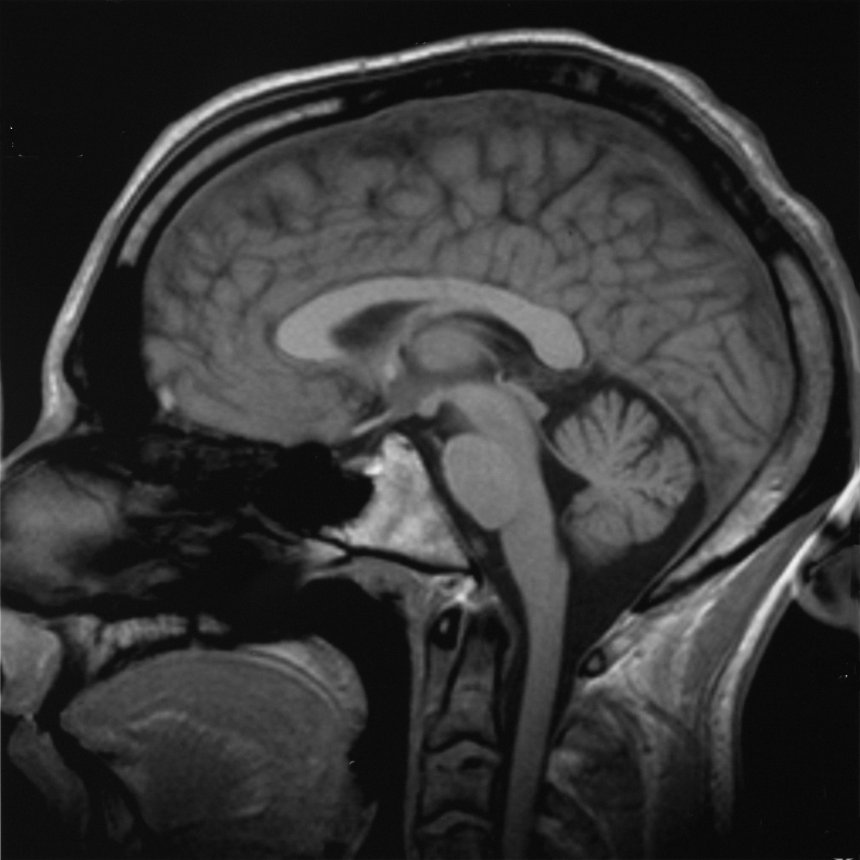

An equally important sector that uses stainless steel is medicine. It is used to make surgical instruments, orthopedic implants, operating tables, and treatment room equipment. Thanks to its biocompatibility and resistance to disinfectants, stainless steel is widely used in medical equipment, where sterility and durability are crucial.

Stainless steel also plays a significant role in building and architecture. It is used for structural elements, facades, railings, stairs, roofs, and ventilation systems. Its weather resistance makes it ideal for outdoor use, while its elegant appearance adds a modern touch to architectural designs.

Stainless steel is used into construct the chemical and petrochemical industries, stainless steel is used in the construction of pressure vessels, pipelines, and chemical reactors. Its resistance to aggressive chemicals allows it to transport and store acids, alkalis, and salt solutions. Its high operating temperature and mechanical strength make it a key material in refineries, power plants, and chemical plants.

It’s also impossible to ignore the use of stainless steel in the motor and aerospace industries. It is used for exhaust systems, body components, fuel tanks, bolts, and fasteners in automobiles. In the aerospace industry, meanwhile, it is used for jet engine components, fuselages, and fuel systems, where resistance to extreme temperatures and corrosion is crucial.

Stainless steel is also widely used in the maritime industry. Its high resistance to seawater and salt makes it an ideal material for rigging, ship structural components, propellers, fuel tanks, and oil rig equipment. Alloys with the addition of molybdenum and nickel are characterized by increased corrosion resistance, which allows them to be used for a long time in harsh conditions.

Thanks to its unique properties, stainless steel is used in many industries. It is a versatile, durable, and resistant material that has been a cornerstone of modern engineering and technology for over a century. Regardless of its application, its importance in various industries will continue to grow, thanks to this remarkable material’s ever-evolving production and processing methods.

Below is a video explaining why SpaceX uses stainless steel to build rockets. You can watch the video on YouTube by clicking here.

What is stainless steel – summary

Stainless steel is a unique material used in almost every industry. Its corrosion resistance, durability, aesthetic appearance, and hygienic properties make it indispensable in the construction, medical, food, chemical, aerospace, and automotive industries. Thanks to its various varieties, its properties can be adapted to specific conditions of use, making it a versatile and highly functional material.

At the same time, it should be remembered that stainless steel also has certain limitations, such as higher cost and difficulty in processing. Nevertheless, its advantages far outweigh these, and the continuous development of production technology allows it to further improve its properties and increase its efficiency. The modern world could not function without stainless steel, a material that has remained one of the pillars of modern engineering and industry for more than a century.

If you want a stainless steel processing company, contact us by clicking the button below.