Copper and its alloys

Table of contents

Among non-ferrous metals, copper occupies a special position, both in terms of its physicochemical properties and the breadth of its industrial applications. Humans have used it since ancient times, and today, despite the development of advanced materials, it remains one of the key engineering raw materials, whose importance is not waning but constantly growing. This is due to its unique set of properties, which make copper not only a versatile material but also one that is difficult to replace.

One of the most distinctive features of copper is its very high electrical and thermal conductivity, second only to silver. This makes it suitable for use wherever low energy losses are crucial, such as in power engineering, electronics, cooling systems, and heating devices. Moreover, its resistance to corrosion, even in humid and chemically active environments, makes it a durable and reliable material ideal for water, heating, and industrial applications.

Also important is copper’s excellent plastic workability, both cold and hot, which enables it to be shaped into complex components without compromising quality. Its ease of soldering and welding, as well as its good compatibility with many other materials, make copper a popular choice for composite systems and hybrid structures.

Copper also forms the basis for many valuable alloys, the most important of which are brass and bronze – materials with significantly different mechanical, chemical, and technological properties. By carefully selecting alloying elements, it is possible to create materials tailored to particular operating conditions – from structural elements to precision equipment parts.

Today, copper is no longer just a utility metal, but a strategic technological resource whose properties and availability influence the development of sectors such as renewable energy, electromobility, electronics, aviation, and urban infrastructure. Its role in the modern technological industry cannot be overestimated – and that is why it deserves in-depth analysis.

Physical and chemical properties of copper

Copper is one of those metals that stand out for their extremely favorable combination of physical and chemical properties, making it one of the most versatile and sought-after technical materials. Its unique character is apparent at first glance – its warm, reddish-gold color and metallic luster are the result of the specific interaction of light with its electronic structure.

One of the most important features of copper is its very high electrical conductivity, which is around 58 MS/m, second only to silver. Thanks to this property, copper is irreplaceable in electrical engineering – from power cables and motor windings to connectors and integrated circuits. Its high thermal conductivity, reaching 390 W/m·K, also makes it an ideal material for components requiring rapid heat dissipation, such as radiators, heat exchangers, and electronic cooling systems.

Copper has a relatively high density of approximately 8.96 g/cm³, which affects its weight in structures, but also indicates a compact, face-centered crystal structure. This structure is highly conducive to plasticity and workability, enabling easy rolling, stamping, drawing, and forging. Even after intense deformation, copper retains its ductility, and its structure allows for relatively easy stress relief through annealing.

From a chemical point of view, copper belongs to the noble metals – it exhibits high resistance to atmospheric corrosion. When in contact with moisture and air, it forms a protective layer of patina. It is resistant to many chemical agents, including seawater, but is affected by specific oxidizing acids, such as nitric acid. In the presence of sulfur compounds, it can form sulfides, which in practice requires adequate surface protection in some industrial environments.

It is also worth noting that copper has excellent biocidal properties, making it suitable for use not only in industry but also in medicine, sanitary installations, and construction. Its unique biological activity allows it to limit the growth of bacteria and microorganisms on its surface, which is of great importance in the context of hygiene and health safety.

Chemically, copper can occur in several oxidation states, but the most important of these is Cu²⁺, which forms the basis of many copper compounds used in the chemical and electrochemistry industries. The reactivity of copper with certain elements also allows for the creation of a wide range of valuable alloys, which will be discussed later in this article.

Technological and processing properties

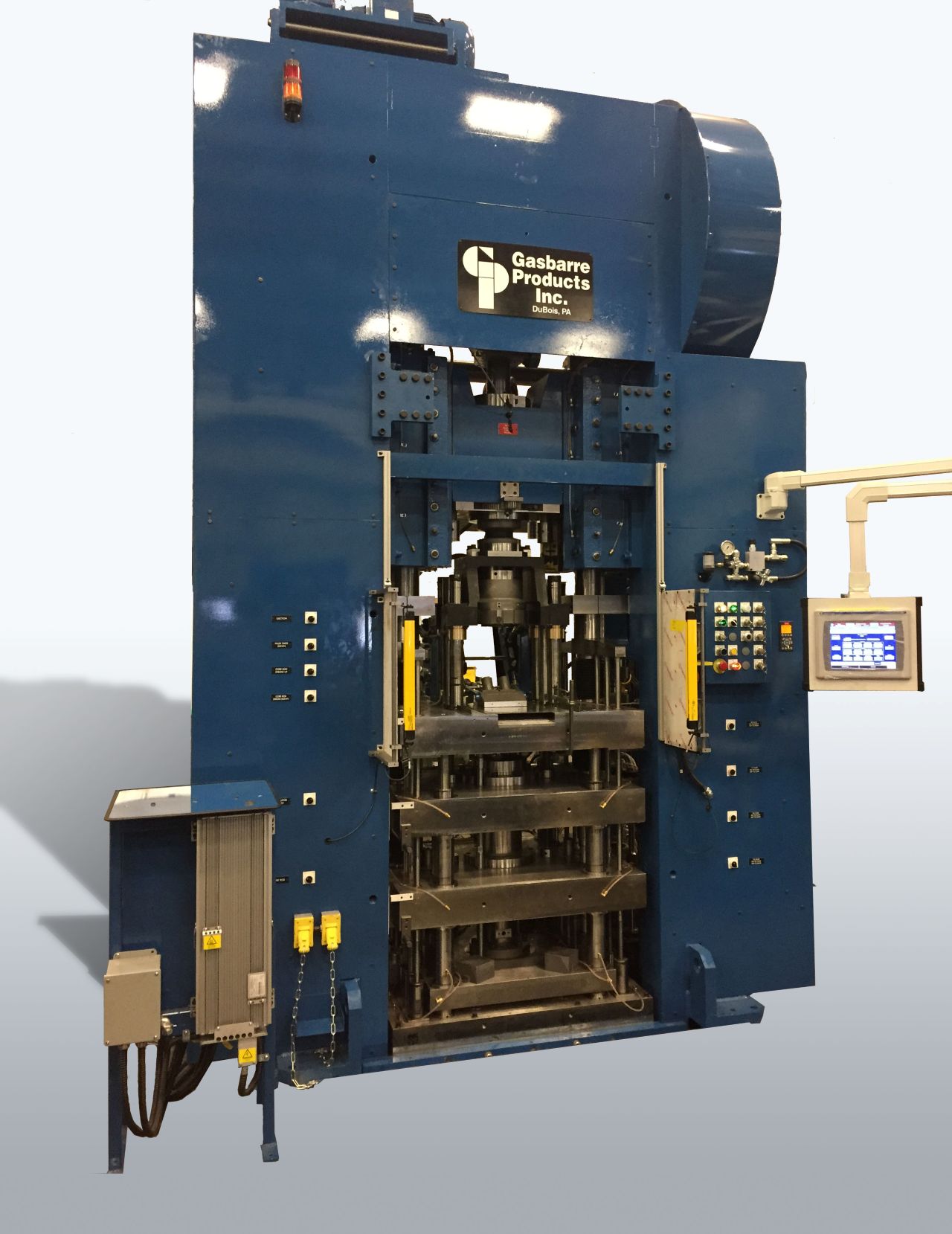

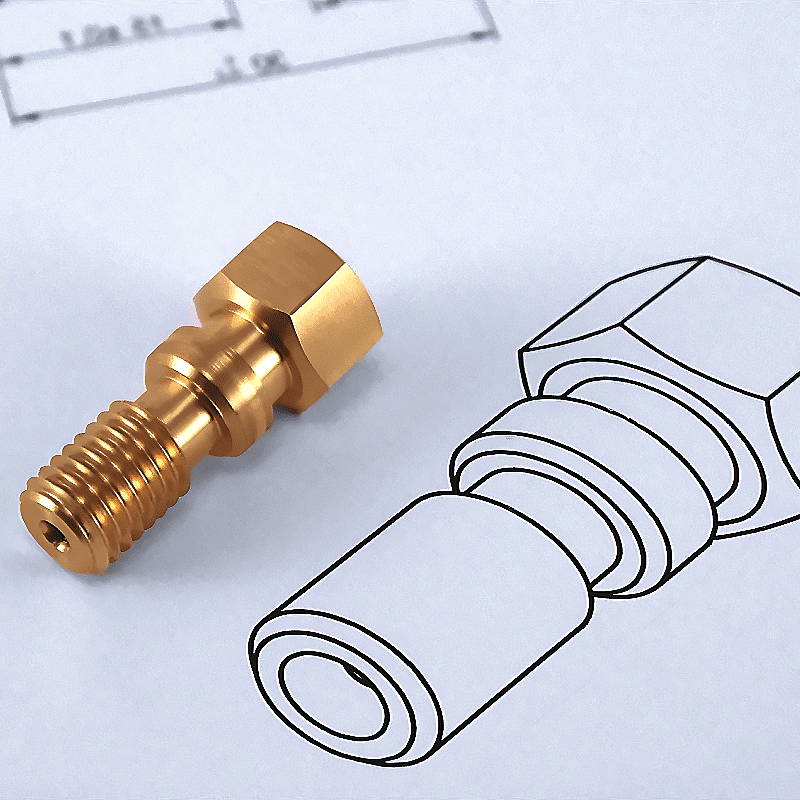

One of the most significant advantages of copper as an engineering material is its exceptional susceptibility to various technological processes, both cold and hot. This property determines its wide range of applications in the metal, electrical engineering, installation, and precision industries. Copper is easy to shape, join, and modify, allowing it to be used for both complex geometric elements and delicate wires.

Copper is characterized by excellent plasticity, which allows it to be intensively deformed without risk of cracking. This property is particularly appreciated in sheet rolling, wire drawing, and pipe and strip extrusion. Its RSC crystal structure facilitates the movement of dislocations, thus reducing plastic resistance during deformation. Copper can also be effectively hot-worked, and the resulting semi-finished products exhibit high surface quality and dimensional stability.

During heat treatment, copper exhibits the ability to fully relieve internal stresses and restore its plasticity, which is particularly important after intensive cold working. Recrystallization annealing processes allow internal stresses to be removed and the material’s physical properties to be restored to homogeneity, which is crucial in the production of precision components.

Copper is well-suited for joining by soldering, brazing, and gas welding, which enables the construction of durable and tight connections in industrial, refrigeration, and sanitary installations. Thanks to their resistance to oxidation and high thermal conductivity, copper joints retain their properties for an extended period, even under elevated temperatures.

In the context of machining, copper is a relatively complex material due to its ductility and tendency to clog tools; however, the right choice of parameters and the use of high-speed steel or carbide blades allow for high surface quality. In addition, copper is characterized by very good polishability and galvanizability, which allows for high purity and aesthetic surfaces.

These properties enable copper to be processed with high precision and repeatability, which is particularly important in modern industries where the precision of workmanship and stability of performance parameters play a decisive role.

Electrolytic copper

In applications where maximum chemical purity and the highest level of conductivity are crucial, electrolytic copper proves to be irreplaceable. It is a form of copper obtained by electrolysis, in which impure copper, acting as the anode, is dissolved in an electrolyte and then deposited as pure metal on the cathode. As a result of this process, it is possible to obtain a material with a copper content exceeding 99.9%, often reaching a purity of 99.99%.

Such a high level of purity translates directly into excellent electrical and thermal properties, which is why electrolytic copper is commonly used in the production of power cables, motor windings, transformers, and high-frequency system components, where even minimal transmission losses could affect the functioning of the equipment. Its low resistance enables the design of efficient and compact solutions, which is of great importance in the electrical engineering and electronics industries.

The high purity of this copper also allows it to be used in vacuum and chemically sensitive conditions, such as in nuclear technology, cryogenics, and in scientific apparatus and medical devices—the absence of non-metallic impurities and minimal contamination guarantee stable properties even in the most demanding operating environments.

In addition to its electrical properties, electrolytic copper is also distinguished by its high structural purity, which has a positive effect on its plasticity, homogeneity, and resistance to cracking during processing. This is why it is often used as a raw material in the production of semi-finished products intended for further processing, such as rolling, drawing, or cold forging.

Although its production cost is higher than that of standard copper grades, its unique performance parameters justify its use where reliability and precision are of paramount importance.

Copper alloys

Despite its excellent performance properties, pure copper has limited applications where higher mechanical parameters are required. This is why its alloys, which – through the addition of appropriate elements – allow for significant modification of the mechanical, chemical, and technological properties of copper, while retaining many of its advantages, such as high conductivity and corrosion resistance, play such an important role in technology.

In terms of technical classification, copper alloys are divided primarily according to the type of main alloying component. The most important groups are brasses, i.e., copper alloys with zinc, and bronzes, in which the dominant additive is usually tin. However, other elements such as aluminum, silicon, phosphorus, lead, or manganese may also be used. There are also copper alloys with nickel, known as copper-nickels, which are characterized by exceptional corrosion resistance in aggressive environments.

Thanks to this wide variety, it is possible to design alloys with very different properties – from high mechanical strength, hardness, and wear resistance to special physical properties such as a low thermal expansion coefficient or good solderability. These alloys can be formed using various methods, including casting and plastic working, which allows them to be widely used in multiple industries.

The importance of copper alloys also stems from their chemical resistance and surface aesthetics, which translate into their use not only in technology but also in architecture, jewelry, and the applied arts. Brass, which combines good technological properties with an attractive appearance, plays a special role here, as does bronze, known for its durability and resonance, used, among other things, in musical instruments.

Brass

Brass is one of the most common groups of copper alloys, in which the basic alloying component is zinc. Their popularity stems from a very favorable combination of mechanical, technological, and aesthetic properties, making them an extremely versatile material in both industry and everyday use.

In terms of structure and chemical composition, brass can be categorized into single-phase and two-phase types. Single-phase brass, containing up to approximately 30% zinc, is characterized by excellent plasticity and ease of cold working, making it an ideal material for rolling, drawing, and stamping. Two-phase brass, on the other hand, with a zinc content of up to 45%, exhibits greater strength and hardness, but is less susceptible to cold deformation. Thanks to this diversity, it is possible to adapt brass to a specific technological function optimally.

One of the most significant advantages of brass is its excellent resistance to atmospheric and water corrosion, which makes it widely used in sanitary installations, fittings, hydraulics, and components exposed to moisture and varying environmental conditions. Additionally, thanks to their low friction coefficient and wear resistance, brass alloys are utilized in bearings, bushings, guides, and other machine components where smooth sliding properties are essential.

small amounts of lead, which improves chip brittleness and increases tool life. Their ability to be polished, soldered, welded, and given attractive surface finishes also makes them a valued decorative material – from fittings and musical instruments to interior design elements.

The properties of brass can be further modified by introducing other elements, such as aluminum, manganese, tin, or nickel, which allows for the production of special alloys with increased strength, abrasion resistance, or anti-magnetic properties. Such variants are used, among others, in the energy sector, shipbuilding, aviation, and automation.

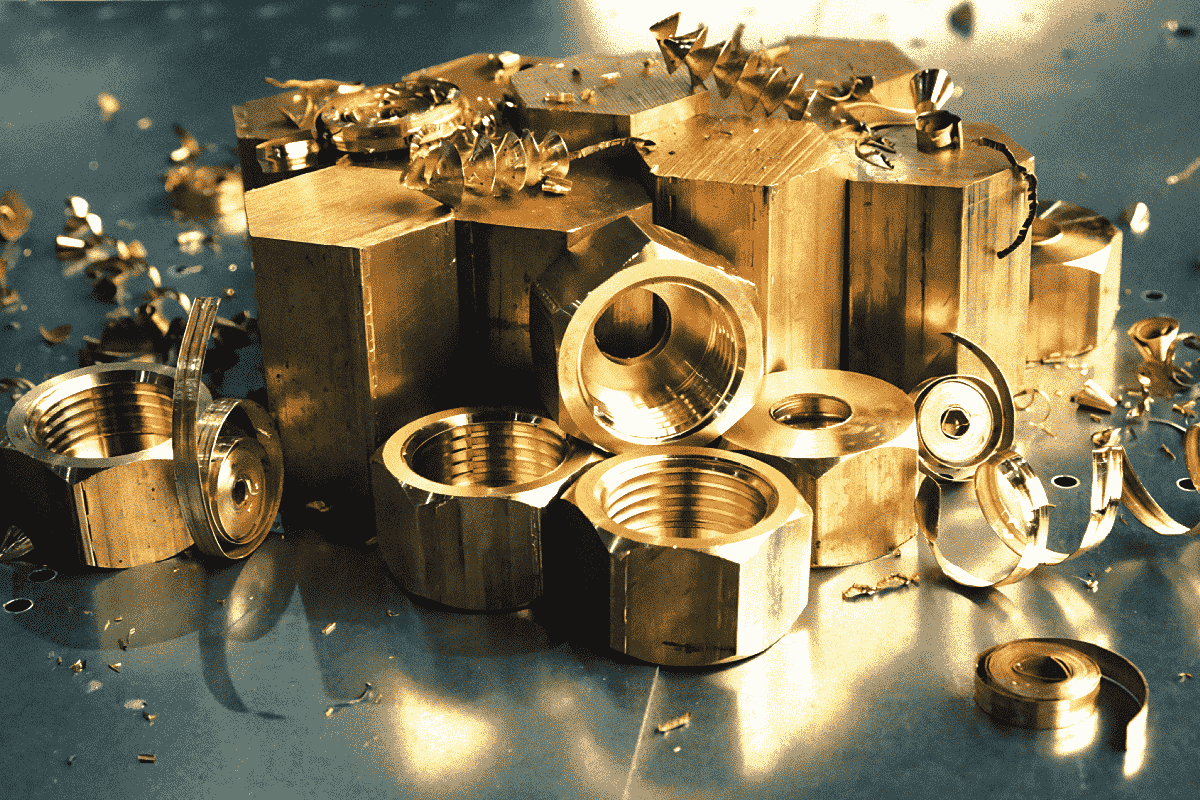

Bronzes

Bronzes, alongside brasses, are the second most important group of copper alloys; however, in their case, the main alloying component is not zinc, but rather another group of elements, most often tin, along with aluminum, silicon, beryllium, manganese, or phosphorus. As a result, bronzes are distinguished by significantly better mechanical and strength properties, which makes them suitable for use where the material is required to have high durability, abrasion resistance, and stability in difficult conditions.

The structure of bronzes is more complex than that of brasses, and their microstructure may contain various phases and precipitates that give them specific functional properties. Tin bronzes, which are the oldest alloys known to man, are characterized by excellent corrosion resistance, high hardness, and wear resistance, which is why they are used in slide bearings, fittings, machine castings, and mechanical parts operating under heavy loads.

Aluminum bronzes, on the other hand, are characterized by exceptional strength, resistance to corrosion in seawater, and low weight, which makes them ideal for use in the shipbuilding, aviation, and chemical industries. Silicon and manganese bronzes, on the other hand, have good elastic properties, abrasion resistance, and dimensional stability, making them ideal for springs, connectors, and precision automation components.

Another important variety is phosphor bronze, which, thanks to its phosphorus content, exhibits excellent abrasion resistance, low friction coefficient, and high hardness, while maintaining good plasticity and conductivity. As a result, they are used in the production of electrical contacts, membranes, gears, and as a material for spring sheets and strips.

Bronzes can be both cast and plastically processed, making them a versatile material available in various forms of semi-finished products – from pipes and rods to sheets and castings with complex shapes. Their high durability in friction conditions and chemical resistance make them irreplaceable in many areas of the heavy and precision industry.

Copper and its alloys – summary

Copper and its alloys play a key role in the development of modern technologies and industrial infrastructure. Their unique properties – from excellent electrical and thermal conductivity, through corrosion resistance, to excellent workability – make them indispensable in almost every branch of the modern economy. It is not easy to imagine the energy, electrical engineering, transport, or construction sectors functioning without these materials.

The high purity of electrolytic copper enables the construction of efficient and durable energy transmission systems, and its biological resistance makes it a valued material in sanitary and medical installations. In turn, the diversity of alloys – ranging from commonly used brasses to specialized bronzes – enables the properties of the material to be precisely tailored to the needs of a specific application, whether in mechanical structures, precision equipment, or devices operating in harsh environments.

The economic and environmental aspects are also important – copper and its alloys are easily recoverable and almost fully recyclable materials, which aligns with the principles of sustainable development. The possibility of repeated use without loss of quality makes them not only functional but also environmentally friendly.

The importance of copper as a strategic raw material is expected to continue growing. As the world transitions to renewable energy, electromobility, and automation of industrial processes, the demand for this metal and its alloys will steadily increase. In this context, understanding the properties, processing, and applications of this material is crucial for engineers, designers, and technologists who aim to leverage the opportunities it offers effectively.