CNC machining or 3D printing

CNC machining or 3D printing – a comparison of modern parts manufacturing technologies

In this article, you will find a clear overview of the basic features of both manufacturing technologies, allowing you to choose the appropriate parts manufacturing method. In summary, we have discussed several main aspects that give you an idea of the strengths and weaknesses of each technology.

The principle of manufacturing parts

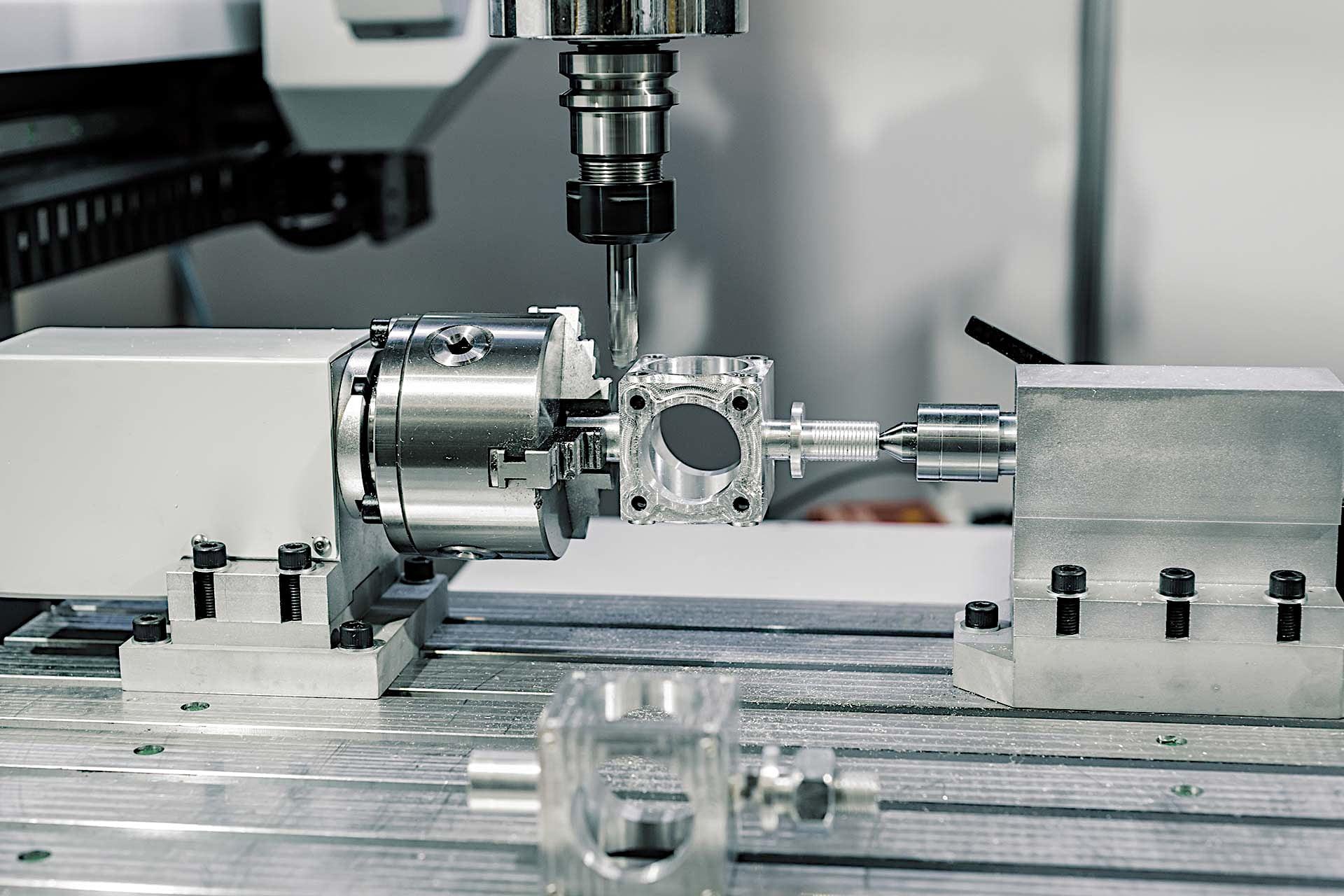

The fundamental distinction between 3D printing and machining is that 3D printing is an additive manufacturing method, whereas CNC machining is subtractive. This means that the CNC machining process starts with a block of material (called a blank), and by cutting out the material, the designed part is created. On the other hand, printing involves creating components by constructing them layer by layer, utilizing materials like resins, plastics, or metal powders. An energy source, such as a laser, fuses these material layers to create the final part.

Materials

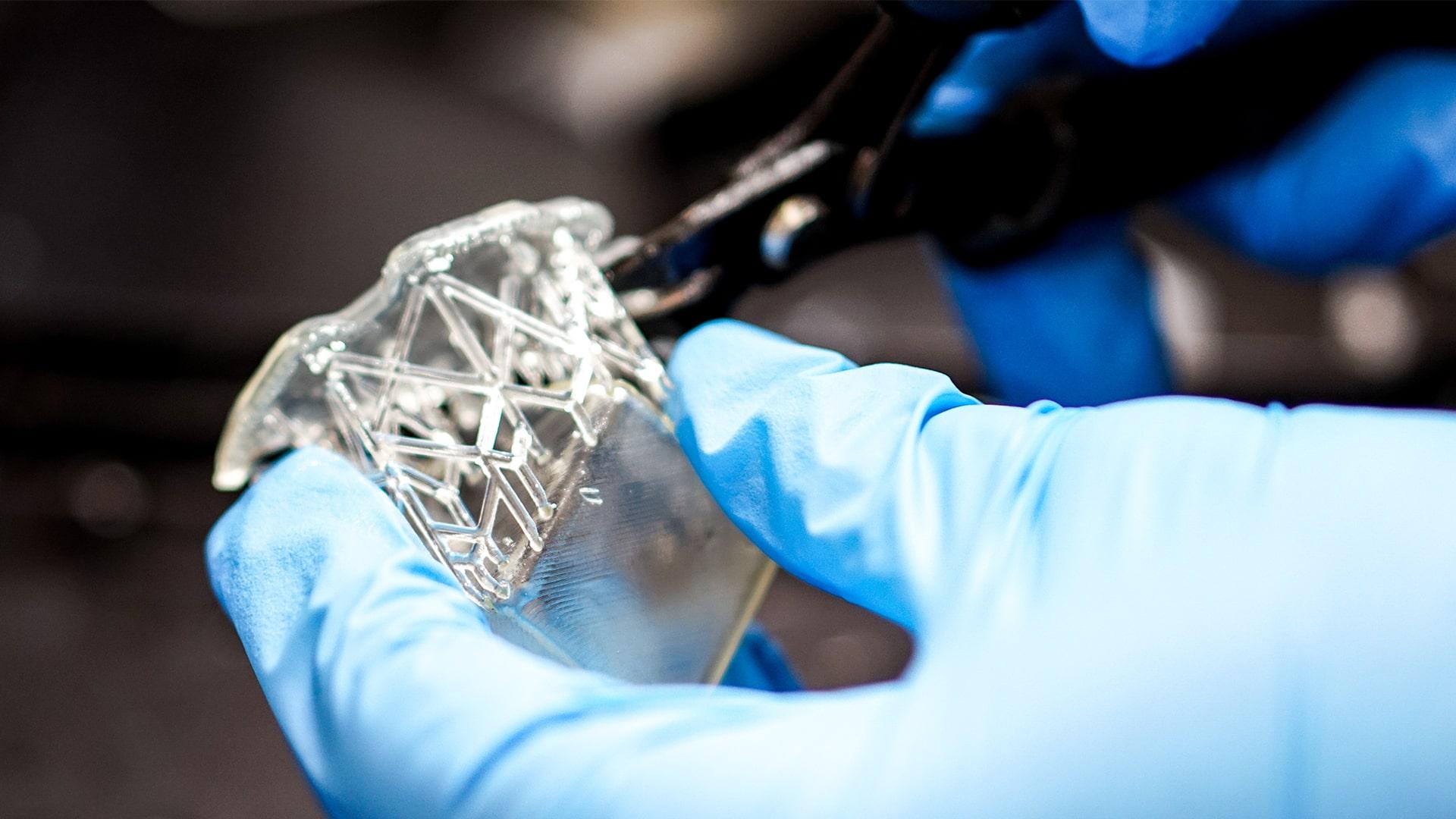

Regarding available materials, machining offers much more freedom of choice. Metals and their alloys are the primary raw material in this technology, but plastics, wood, foams, or even waxes can also be successfully processed. 3D printing commonly uses thermoplastics, photopolymers, and resins. Printing in other materials, such as metal or ceramics, is also possible, but these are still niche applications.

Accuracies

While there are many variations of 3D printing technology, CNC metal machining surpasses all these processes in terms of achievable manufacturing tolerances. This is mainly because the part is created in layers during printing, and unevenness between them is unavoidable. Of course, the smaller the layers, the higher the printing resolution. However, the mirror-like surfaces created after CNC machining are still beyond the reach of this technology.

Part geometry

The primary advantage of 3D printing lies in its capability to produce parts with intricate and complex geometries, particularly those featuring internal structures. Also, thin-walled parts are easier to produce with this technology. Due to the need for material removal tools, machining has a number of limitations on this account related to the geometry of the tools and their access to the machined surfaces.

Manufacturing time and costs

In the case of printing, the production preparation process is simple and quick, and startup costs are lower than in the case of machining. However, printing, especially of larger parts or at high resolution, can be time-consuming. In CNC machining, on the other hand, a more labor-intensive and lengthy process preparation is required. However, manufacturing the part itself can often take only a dozen seconds or so.

Unit costs depend on the number of parts required and how quickly you need them. For larger quantities of parts (more than 100 pieces), machining is usually the best choice. For a single prototype, choose this production method as long as it is printable – you will get it faster and cheaper.

Conclusion

In conclusion, no perfect, universal technology for manufacturing parts exists. Although both methods are very useful and have advantages, the choice of the most suitable one should depend on factors such as the required material, geometric complexity, production volume, and budget.

The vast majority of parts in industrial applications are machined parts using CNC technology because of the accuracy and precision of manufacturing achieved, the high productivity, and the repeatability of the process.

3D printing, on the other hand, is mainly used in cases where: